Coil nails have transcended the category of simple consumables in modern fastening systems. As automated nailing equipment becomes the norm, coil nails are evolving toward greater precision, consistency, and compatibility. Manufacturers today must not only meet standards like EN14592 for structural timber fasteners, but also address critical technical factors such as tool compatibility, collation stability, coating adhesion, and long-term corrosion resistance.

High-quality coil nails begin with controlled wire drawing from low-carbon Q195 steel, delivering reliable formability and low breakage rates. For surface protection, UNION offers three coating options tailored to environmental exposure levels: Electro Galvanized (EG), Hot-Dip Galvanized (HDG), and 304/316 Stainless Steel, providing scalable corrosion resistance across applications.

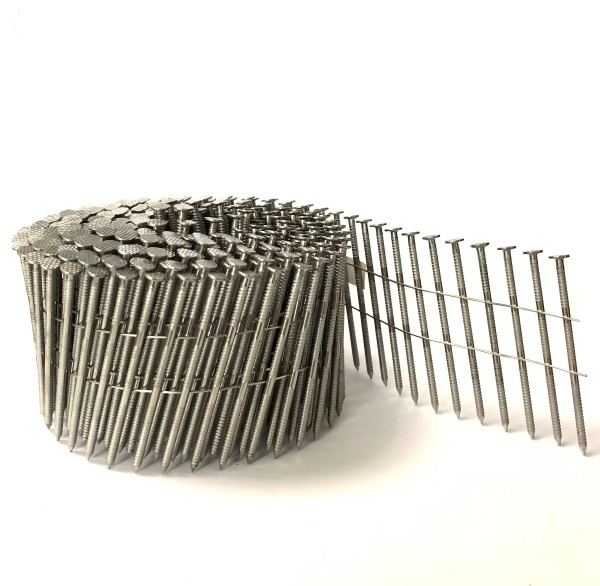

While coil nails are broadly categorized into 15-degree wire coils and 16-degree plastic strips, real-world tool compatibility goes beyond angle. Factors like collation material flexibility, coil tension, and nail head tolerance vary between brands. UNION fine-tunes its production to align with top global models — MAX, BOSTITCH, SENCO, APACH — ensuring jam-free, high-speed performance even in industrial-grade operations.

Conclusion: Behind the seeming standardization of coil nails lies a quiet competition of precision, materials, and integration capabilities. With nearly 30 years of export experience, UNION focuses on tool compatibility and long-term performance, delivering coil nail solutions trusted by global industrial leaders.

Post time: Apr-16-2025