Other machines

-

Self Drilling Screw Heading Machine

Screw heading machine is a kind of cold heading equipment for producing screws, which is mainly a metal processing machine for basic screw forming. Strong flexibility and convenient length adjustment are suitable for small batch production or proofing. Yield and quality are directly related to operators. Screw forming There are two types of screw shape forming and thread forming: the equipment used for shape forming is a heading machine, which adopts cold heading processing and forming; the equipment used for thread forming is a tooth rolling machine, which adopts extrusion processing and forming. It has better surface quality and higher dimensional accuracy. Due to the cold work hardening in the upsetting process, the amount of deformation should not be too large reduce cracking

-

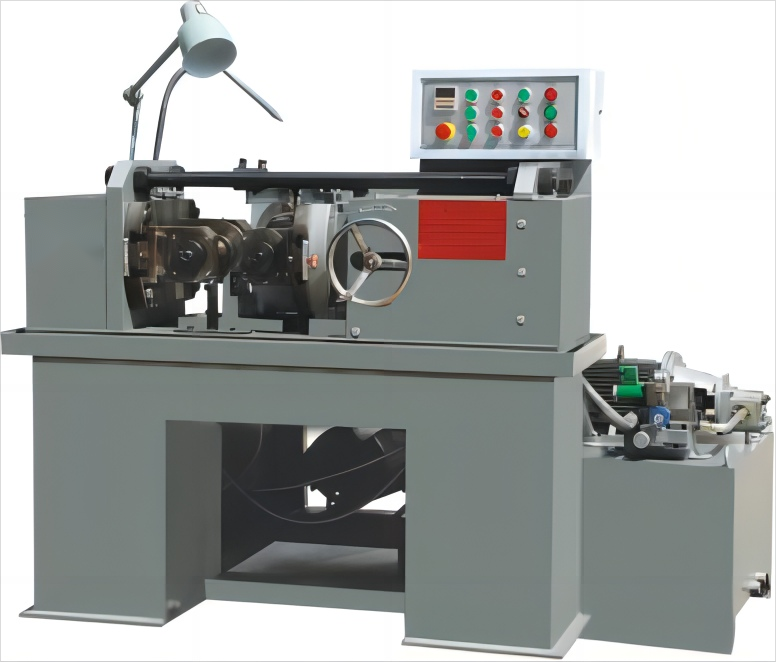

Three-axis thread rolling machine Z28-16

The machine is mainly composed of three identical sets of thread rolling shaft assemblies,three sets of identical sliding sleeve cylinder hydraulic systems.transmission mechanisms, shifting mechanisms,electrical systems,and cooling systems.

The fuselage supports three identical cylinders, and the cylinder bottom supporta three identical thread rolling shaft assemblies for synchronous feed and retraction linear motion.The clamping of the workpiece is completed,and the retracting process is cut in and released;the three output rolling shafts of the transmission output drive shaft rotate in the same direction at the same speed to complete the rolling process of the thread.

-

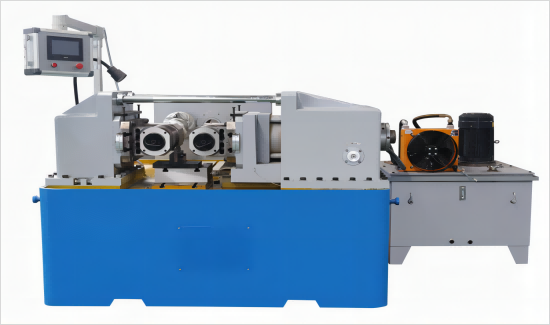

Thread Rolling Machine Model Z28-80

This model is widely praised for its rational price,easy maintenance and high quality.Besides axial and radial process,it is used to process regular and irregular bolt,through screw etc.with optional embossing roller.The through screw made with this machine in ZheJiang Standard Parts base has been exported to US,Canada and Europe. This machine can be based on user demand is equipped with automatic feeding device.

-

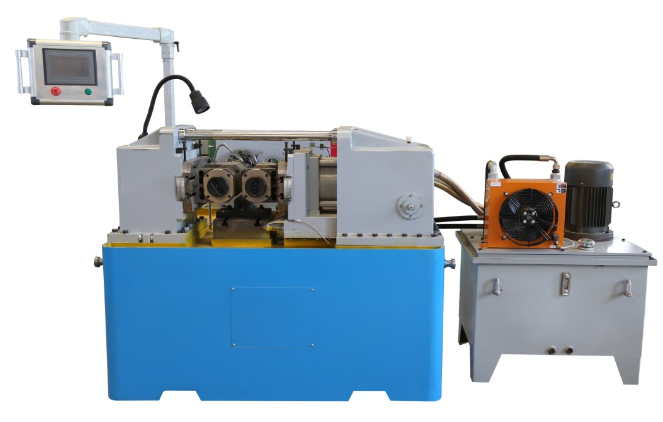

Thread Rolling Machine Model Z28-200

This model mainly is used for pressing precision standard parts of extermal thread and high strength,including regular thread,trapezoid thread and modulax thread.The objective material to be processed inchcde carbon steel,alloy steel and nonferrous metal with elongation over 10% and tensile strength less than 1000N/mm2.This machine can be based on user demand is equipped with automatic feeding device.

-

Thread Rolling Machine Model Z28-400

The construction of the Z28—400 model i made with welded steel plates, this machine boasts a rational structure, which contributes to its overall rigidity and stability. This robust build allows for precise and accurate thread rolling, resulting in superior quality products.

Moreover, the Z28—400 model prioritizes ease of operation. Its user-friendly interface and intuitive controls make it accessible for both experienced operators and those new to the thread rolling industry. The simplicity of its design translates into quick setup and adjustment, further streamlining the manufacturing process

-

Thread Rolling Machine Model Z28-260

This model mainly is used for pressing precision standard parts of extemal thread and high strength, including regular thread .rapezoid thread and modulax thread.The objective material to be processed inchcde carbon stel,lly steel and noferrous metal with elongation over 10% and tensile strength less than 1000NV/mm’. This machine can be based on user demand is equipped with automatic feeding device.

-

Clip Nail Coil Machine

The Clip Nail Coil Machine features an adjustable number of clips to shear, allowing the user to set it as desired.

-

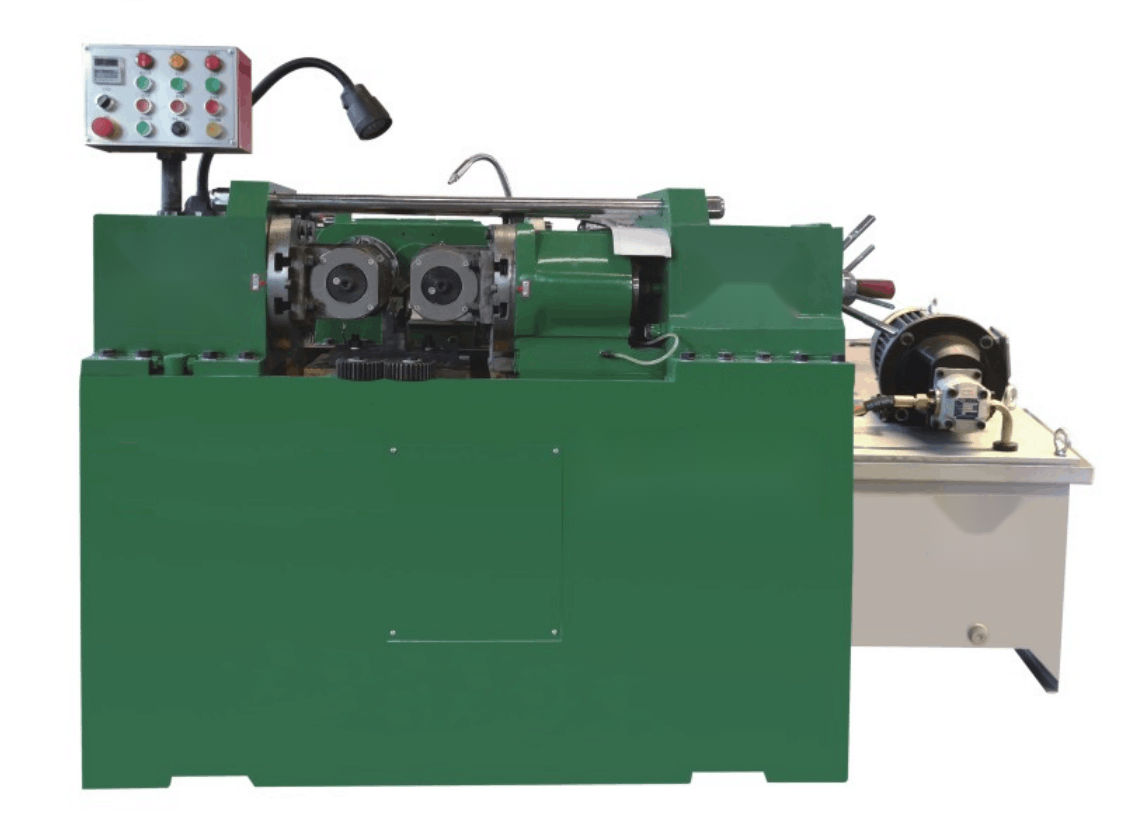

Thread Rolling Machine Model Z28—40

This machine is suitable for rolling forming straight, screw and ring type,etc, with a diameter of of Ø4-Ø36 in cold state. Equipped with screw moulds, it’s also capable of manufacturing concealed wire (threads hidden inside the workpiece)、total screw. Formed by welding steel plates, this machine possess reliable quality, reasonable structure, and it’s easy to operate. We believe this is the ideal machine for you to produce standard and even non-standard thread.

Automatic feeding device is available to be equipped according to your demand.

-

Winding Machine

Equipment structure reasonable design,whole beautiful, rigid and small error,high precision.

Equipment is hightly effective,the energy conservation,safety,production as high.

The most significant characteristic is equipment good stability,easy operation,easy maintenance,full automatic lntelligent,the vulnerability of low cost.

-

Automatic Hydraulic Staple making machine

This machine is suitable for producing U staple such as N staple, K staple, carton staple, etc.

Heavy punching method is abandoned in this machine, and it adopts a hydraulic system for implementation of components, PLC controlled, with characteristics of safety operation, stable performance, low noise and high efficiency.

-

Automatic Hydraulic FT brad Nail Making machine

1. Automatic hydraulic nailing machine using high pressure oil, low noise, low failure rate, the circuit uses PLC integrated control, unlimited product limit, beautifully produced.

2. Supporting extended conveying equipment, can automatically pick nails, a high degree of automation equipment, reduce picking workers, reduce production costs.

-

Auto Block Cutter

This equipment can be used for automatic cutting of wood chip planer pier, multi-layer board foot pier, solid wood wooden square; cutting length specification can be adjusted, 100*100mm specification can be realized within the double bar at the same time cutting, 100-200mm specification of the single bar cutting. (beyond the conventional length, height range, you can contact the customized)