In the world of precision carpentry and detailed woodworking, Brad Nails often go unnoticed—but their impact is impossible to ignore. These small, slim fasteners are the hidden heroes behind many of the clean, seamless finishes we see in furniture, trims, and cabinetry.

What Makes Brad Nails Unique?

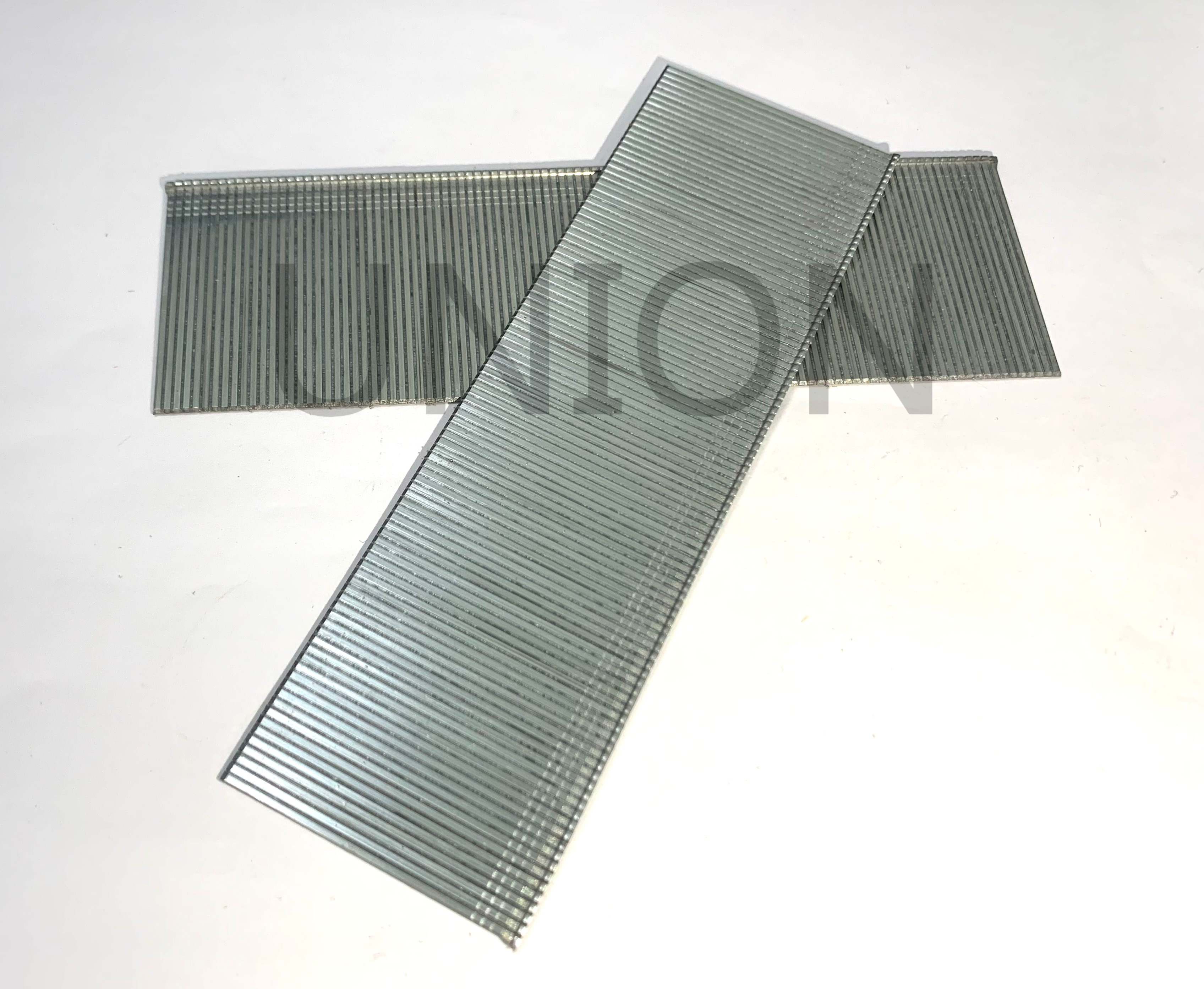

Brad Nails are characterized by their narrow diameter (typically 18-gauge) and small heads, making them ideal for delicate work where splitting or visible nail holes must be avoided. Because they leave such a minimal mark, they’re a favorite for interior woodwork, especially when aesthetics matter.

Unlike finish nails, Brad Nails don’t require as much filling or sanding after installation. This means less touch-up work and more consistent results, saving time for both professionals and DIYers.

Where Brad Nails Shine

Cabinet Making – Perfect for assembling lightweight frames and components.

Trim and Molding – They attach without cracking delicate materials.

Decorative Woodwork – Ideal for attaching small panels or accents without visible damage.

Furniture Assembly – Great for light-duty joints or tack points that need a clean appearance.

They’re often used with pneumatic or cordless nailers, which allow for quick, precise firing in repetitive tasks. For high-efficiency production lines, Brad Nails are not just a convenience—they’re essential.

Material & Quality Matter

At UNION FASTENER, we understand that not all Brad Nails are created equal. The wire diameter, tensile strength, and surface treatment (such as galvanization or stainless steel options) directly affect performance and appearance. We manufacture Brad Nails with consistent wire feed, strict tolerance control, and smooth finishes to prevent jamming and ensure perfect driving depth every time.

Whether you’re building custom furniture or installing intricate trim, Brad Nails offer the precision and subtlety required for professional-level results. Sometimes, it’s the smallest tools that make the biggest difference.

Post time: Apr-24-2025