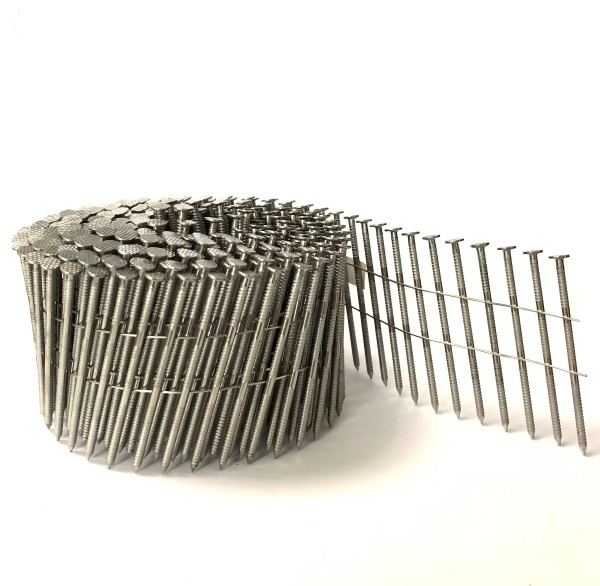

Most people recognize coil nails as “spiral-arranged nails used in nail guns” for quick construction. However, in industrial applications, coil nails embody intricate mechanical design principles, material science, and adaptive engineering across diverse use cases.

1. Why the Spiral Form? It’s More Than Space Saving

The coiled structure optimizes feeding efficiency, shooting stability, and operational safety:

-

Even Weight Distribution: A circular coil ensures minimal balance shift during firing, essential for high-angle operations like roofing or fencing;

-

Resilient Strip Feeding: Copper wire or plastic tape collation absorbs repeated tool vibrations without cracking—a major advantage over stick nails;

-

Extended Capacity: Up to 300 nails per coil reduce reload time, improving workflow speed.

2. Coil Nail Variants Are Engineered for Specific Materials

Different applications require different specs—not all coil nails are the same. Key parameters impact holding power, corrosion resistance, and longevity.

| Spec | Options | Use Case |

|---|---|---|

| Material | Q195 Steel, SS304/316, High-Mn Steel | Woodwork / Marine / Structural |

| Coating | Electro-Galv, Hot-Dip, Dacromet, Epoxy | Anti-Rust, Outdoor, Industrial |

| Shank | Smooth, Screw, Ring | Affects withdrawal strength & grip |

| Head Type | Flat, Dome, Clipped | Determines shear resistance & drive-in force |

Post time: Jul-16-2025