In today’s fast-paced construction and pallet manufacturing industry, choosing the right fastening solution is critical to ensure both efficiency and long-term durability. Among various options, plastic coil nails have emerged as a preferred choice for professionals who demand high performance and reliability.

What are Plastic Coil Nails?

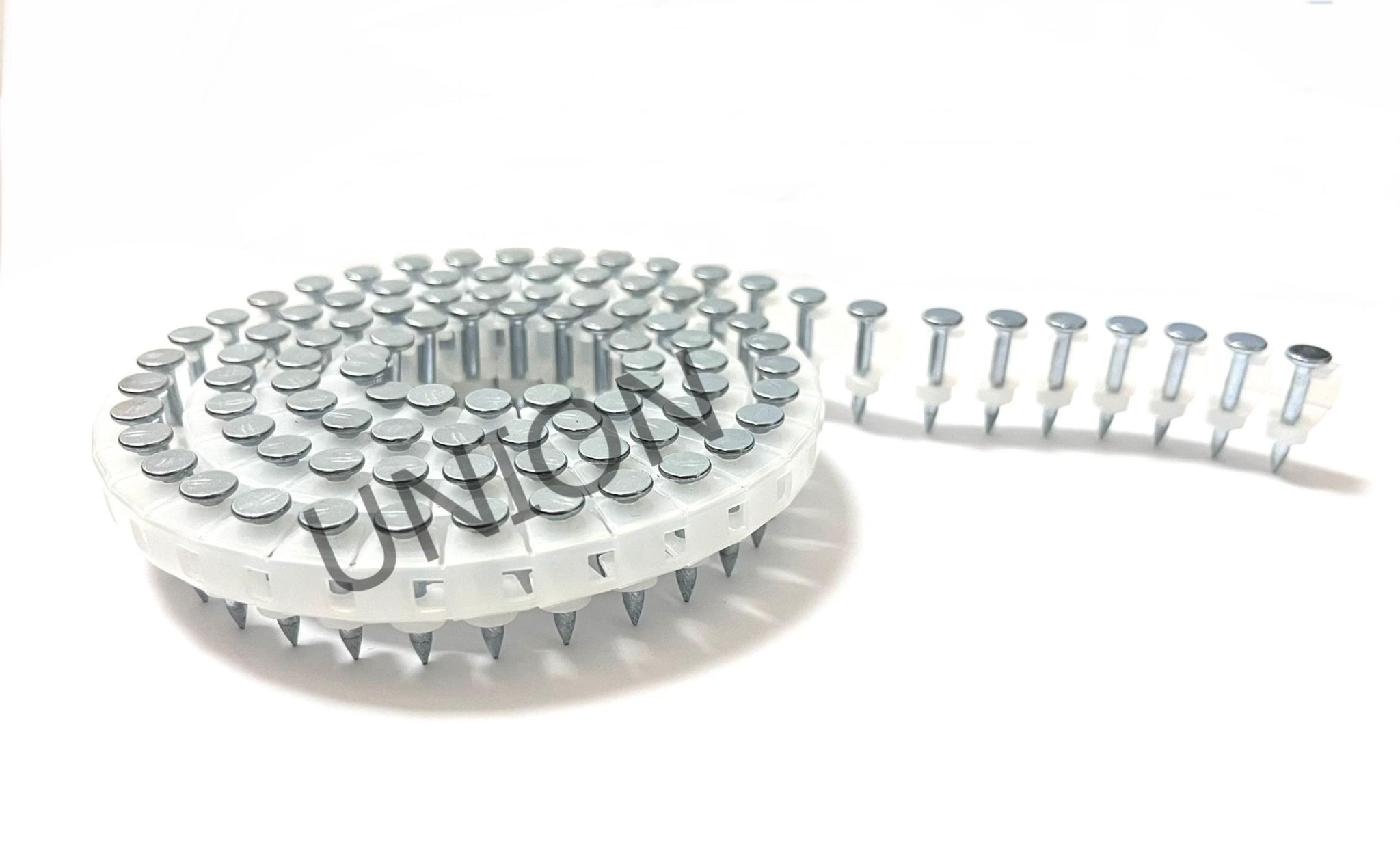

Plastic coil nails are nails collated together with high-quality plastic strips, designed to work seamlessly with coil nail guns. Unlike traditional strip nails, the plastic collation provides smooth feeding, reduced jamming, and consistent firing, making them ideal for high-volume applications. They are commonly used in pallet manufacturing, furniture assembly, and framing in construction.

Key Advantages of Plastic Coil Nails

1. High Strength and Durability

Manufactured from premium wire and quality plastic, plastic coil nails offer strong holding power and can withstand heavy-duty usage. They are resistant to bending and breakage, ensuring that every joint remains secure, even in demanding industrial or construction environments.

2. Enhanced Efficiency

Thanks to their smooth collation, plastic coil nails allow for faster nailing with minimal downtime. The reduced likelihood of jams and misfires means that workers can maintain a steady workflow, improving overall productivity on the job site.

3. Versatility in Applications

Plastic coil nails are highly versatile. They are ideal for pallet production, offering reliable fastening for wood slats, as well as for wooden furniture, crates, and framing projects.

Their performance in various wood types makes them a valuable asset for manufacturers seeking both quality and consistency.

4. Cost-Effective Solution

While providing premium performance, plastic coil nails are cost-effective due to reduced waste from misfires and less downtime from jams. They help businesses save on both materials and labor costs while maintaining high-quality output.

Why Choose Plastic Coil Nails for Your Projects?

For professionals in construction and pallet manufacturing, using the right fasteners can significantly impact the quality and efficiency of work. Plastic coil nails not only enhance productivity but also ensure long-lasting structural integrity. With easy compatibility with standard coil nail guns, they simplify installation and reduce operational issues.

In conclusion, as the demand for efficiency, reliability, and durability grows in modern construction and manufacturing, plastic coil nails stand out as a superior solution. They offer **strength, smooth application, versatility, and cost savings, making them indispensable for professionals seeking high-quality fastening solutions.

Post time: Sep-09-2025