In the dynamic world of construction, where efficiency, durability, and reliability are non-negotiable, plastic coil nails have emerged as a transformative fastener solution. Unlike traditional wire-collated alternatives, these innovative nails combine advanced material science with user-centric design to address the most pressing pain points of builders, carpenters, and contractors worldwide.

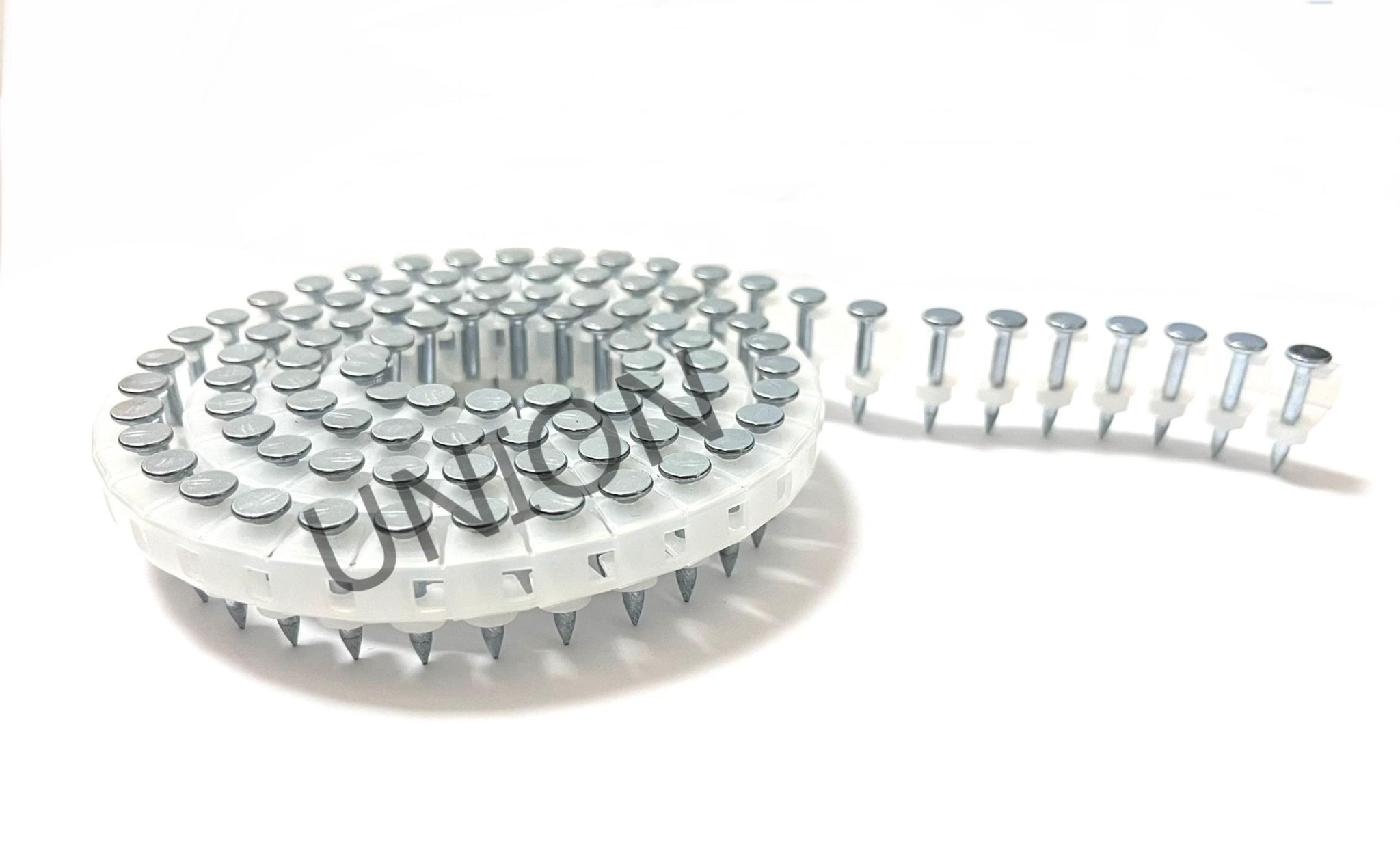

At the core of plastic coil nails’ superiority lies their plastic collation technology. Crafted from high-density, flexible plastic, the collation strip ensures seamless compatibility with 0°/15°/28° coil nailers, allowing for consistent nailing angles without jamming — a common frustration with wire-collated nails . The on-center nail head design further minimizes interruptions, while the strip’s flexibility adapts to the demands of high-volume projects, from framing and siding to fencing and decking . This jam-free performance isn’t just a convenience; it’s a productivity booster, reducing downtime spent unclogging tools and reloading fasteners.

Durability is another defining feature. Most plastic coil nails are manufactured with carbon steel or stainless steel (304/316 grades) shanks, enhanced by galvanized coatings — either electro-galvanized or hot-dip galvanized . These coatings provide exceptional corrosion resistance, withstanding harsh weather conditions, moisture, and even saltwater environments. According to industry tests, hot-dip galvanized plastic coil nails can endure 500+ hours of salt spray without rusting, outperforming standard fasteners in outdoor applications . The diamond or chisel points ensure smooth penetration into structural timber, while ring or screw shank options maximize holding power, preventing loosening over time .

Versatility is a key advantage of plastic coil nails. Available in lengths ranging from 1-1/2” to 4” and diameters of 0.090” to 0.11”, they cater to diverse projects: from lightweight sheathing to heavy-duty framing . Their compatibility with industry standards such as EN 14592, ASTM F1667, and ICC ESR 1539 ensures compliance with global construction regulations, making them a trusted choice for both residential and commercial builds . Additionally, their lightweight design reduces operator fatigue during extended use, while the clean, non-corrosive plastic collation eliminates metal waste, aligning with eco-friendly construction practices .

What truly sets plastic coil nails apart is their user-centric innovation. The high-capacity coil design — holding up to 6,000 nails per coil — minimizes reload frequency, keeping workflows uninterrupted . For specialty applications, such as coastal areas or chemical-exposed environments, 316 stainless steel variants offer superior resistance to corrosion and chemical erosion . Whether used in manufactured housing, pallets, crates, or exterior decking, these nails deliver consistent performance that builders can rely on, project after project.

In a market saturated with generic fasteners, plastic coil nails stand out as a purpose-built solution. They embody the principle that construction tools should work for the user, not against them — combining strength, simplicity, and sustainability in one reliable package. As the construction industry evolves, plastic coil nails continue to set the standard for what a modern fastener should be: efficient, durable, and designed with the end-user in mind.

Post time: Jan-16-2026