In today's fast-developing manufacturing industries, improving production efficiency, streamlining assembly processes, and ensuring product quality have become critical goals across various sectors such as packaging, furniture, construction, and woodworking. As a vital component in high-speed automated nailing systems, plastic coil nails are increasingly adopted by manufacturers worldwide, playing an essential role in modern fastening technology.

Application Advantages of Plastic Coil Nails

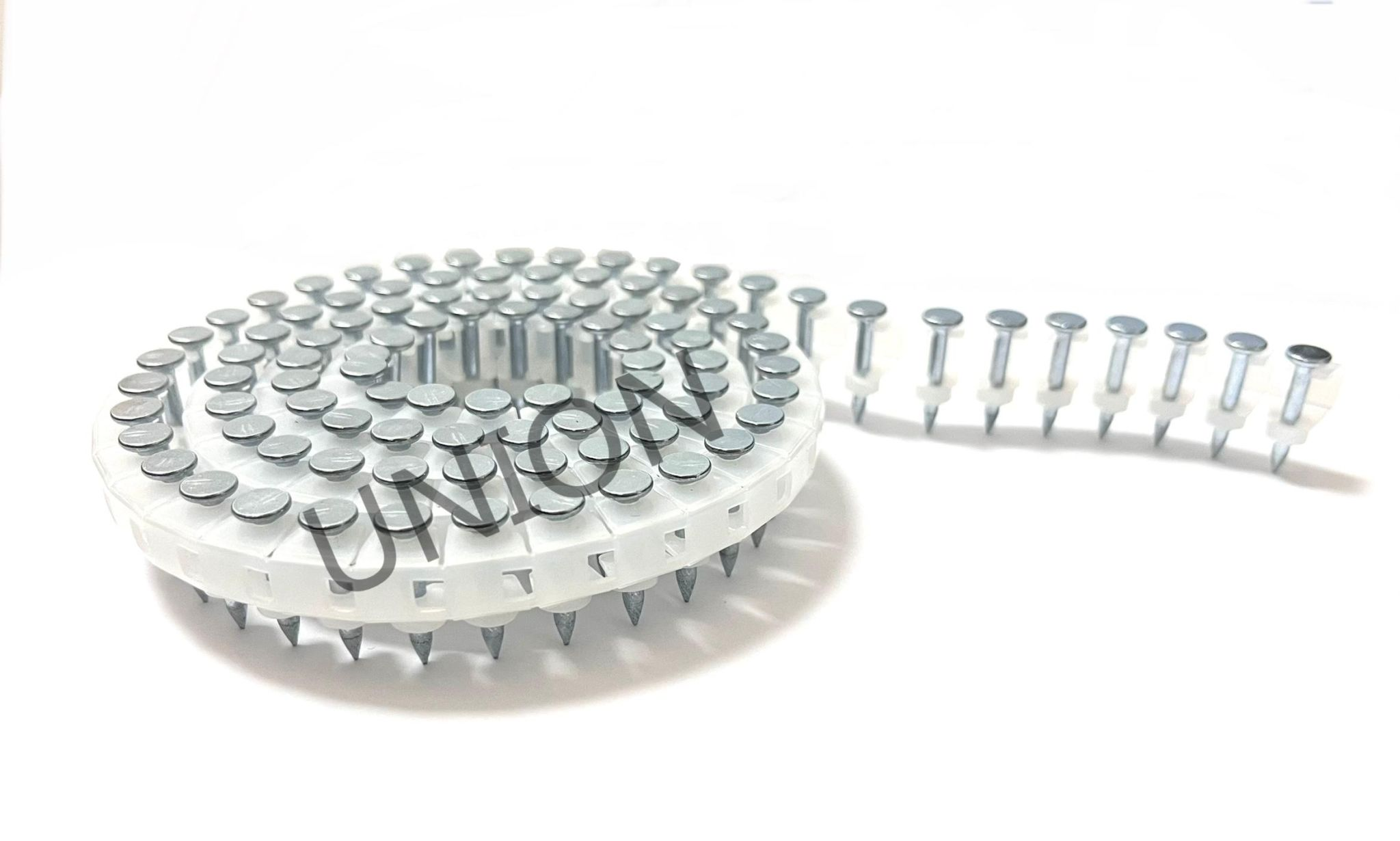

Plastic coil nails are formed by connecting individual nails into rolls with high-strength plastic bands, allowing continuous feeding in high-speed automated nailing equipment. This greatly enhances production rhythm and efficiency while reducing manual labor. Whether used in pallet manufacturing, wooden packaging, furniture assembly, construction framing, flooring installation, or outdoor timber structures, plastic coil nails ensure stable fastening performance and support higher automation levels, consistent assembly, and safe, reliable joint strength.

Stable and Consistent Product Quality

Understanding the importance of coil nails in production, we strictly control quality throughout our manufacturing process:

-

Precision nail dimensions with controlled length, diameter, and tolerances for smooth feeding;

-

High-quality low-carbon steel combined with advanced heat treatment for superior holding power and pull-out resistance;

-

Strong plastic coiling, heat-pressed and neatly formed, preventing coil collapse or band breakage;

-

Broad compatibility with leading coil nailers and automated nailing systems, ensuring smooth, stable operation.

Versatile Applications Across Industries

Thanks to their outstanding performance, plastic coil nails are widely used in:

-

Wooden pallet and crate manufacturing

-

Construction framing and roofing

-

Furniture structures and woodworking assembly

-

Timber homes, gazebos, decking, and outdoor wooden projects

-

Gardening products and landscaping timber work

In all these applications, plastic coil nails not only improve production efficiency but also enhance product durability and reduce repair or service costs throughout product lifecycle.

Flexible Customization for Diverse Needs

To meet various production demands and equipment requirements, we offer a wide range of customized solutions, including:

-

Lengths: available from 32mm to 90mm

-

Nail types: smooth shank, ring shank, screw shank, flat head, round head, D head, and more

-

Surface finishes: electro-galvanized, hot-dip galvanized, dacromet, anti-corrosion coatings

-

Plastic coil colors: multiple color options for easy identification and product management

Our flexible manufacturing and fast delivery help customers enhance production scheduling, optimize inventory control, and reduce overall costs.

Professional Commitment to Excellence

Guided by the philosophy of "quality wins the market, professionalism serves the customer," we continuously invest in advanced production equipment, comprehensive quality control systems, and a professional technical team to ensure every batch of plastic coil nails meets high, stable quality standards. We firmly believe that providing stable products and comprehensive support is the key to helping customers succeed in a highly competitive market.

Moving forward, we sincerely look forward to cooperating with more manufacturing partners worldwide, jointly creating smarter, more efficient fastening solutions, and building a successful future together.

Post time: Jun-13-2025