In today’s fast-paced production environments, precision and reliability are non-negotiable—and that’s exactly what plastic coil nails deliver. Designed for continuous operation in industrial-grade nailers, plastic collated coil nails are the ideal choice for pallet manufacturers, crate builders, and structural frame assembly lines.

Unlike loose nails or paper tape nails, plastic coil nails offer superior durability and resistance to both environmental moisture and mechanical stress. Their flexible plastic collation allows for smooth feeding and reduced jamming, ensuring uninterrupted workflows even under high-speed automated conditions. Each coil is engineered to support long operational cycles, cutting down reload times and maximizing output.

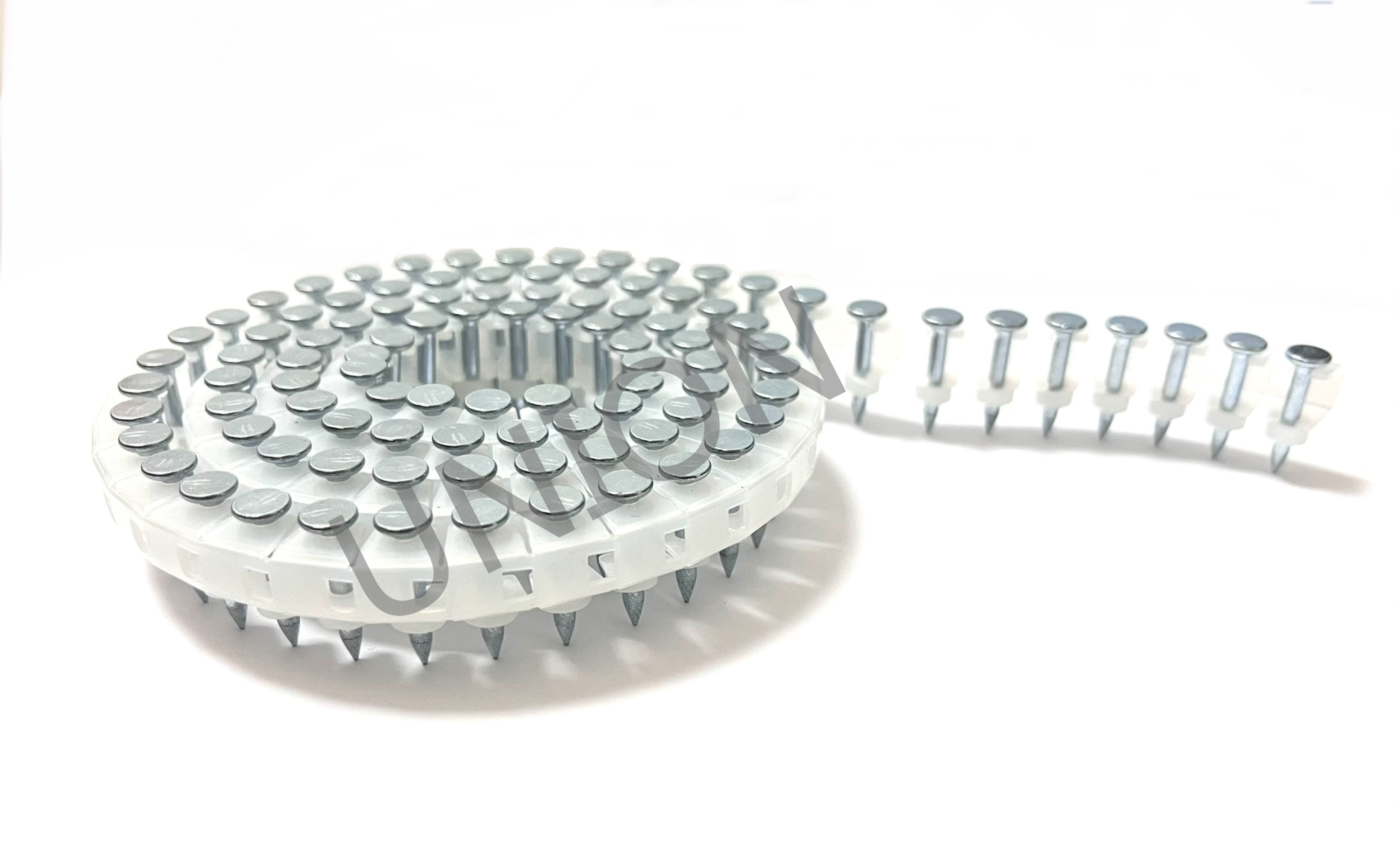

UNION’s plastic coil nails are manufactured with high-quality galvanized wire, providing excellent rust resistance and structural integrity. The nails are uniformly formed with tight tolerance, ensuring each drive is clean and accurate. This consistency is essential for applications where strength and presentation both matter—like export pallets, heavy-duty furniture frames, or construction modules.

Compact in design yet robust in performance, the plastic coil format also offers advantages in logistics and storage. The tight coiling reduces space, while the sturdy plastic strip keeps each nail precisely aligned until the moment of firing. It’s a solution designed not just for efficiency, but also for safety and ease of use.

UNION supports full customization—from nail length and coil count to packaging and strip color—helping partners around the world adapt to market-specific requirements and equipment compatibility. Backed by decades of experience in nail manufacturing, we aim to elevate every project with reliable products that keep production moving forward.

Plastic coil nails are more than a fastening tool—they’re a production upgrade. Choose UNION, and let every coil deliver the quality your work deserves.

Post time: Apr-21-2025