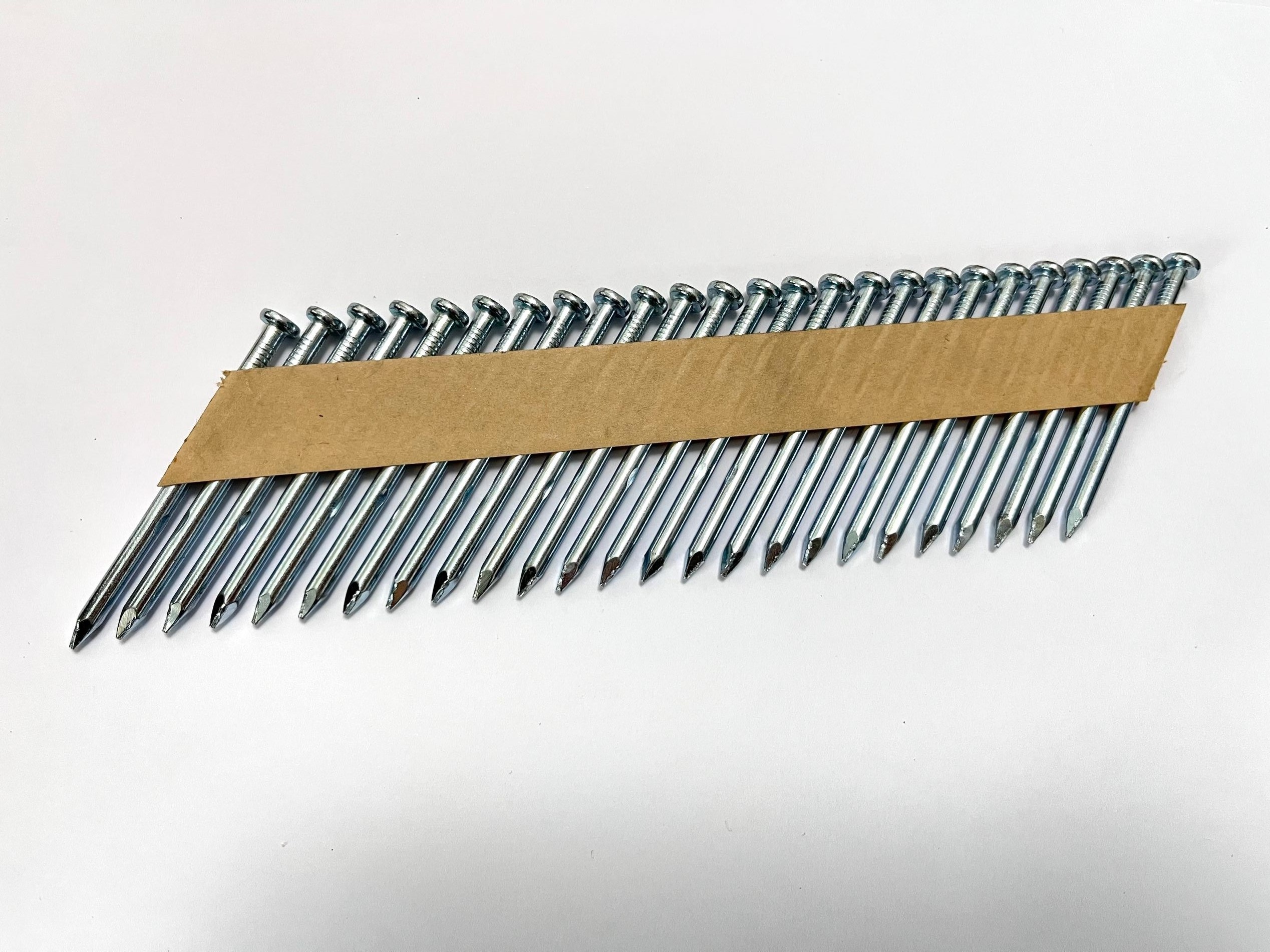

In every optimized industrial system, the balance between speed and reliability is never incidental—it is engineered. Within construction, packaging, and furniture manufacturing, paper strip nails, often overlooked as minor components, are quietly reshaping the technological framework of nailing systems.

Their role extends far beyond fastening. Paper strip nails embody the convergence of structural mechanics, equipment compatibility, uninterrupted workflow, and sustainable manufacturing. The evolution of this small product reflects an industry-wide pursuit of stability, performance, and responsibility.

1. A Critical Element in Intelligent Systems

As nailers become increasingly automated and sensor-driven, paper strip nails are no longer just consumables—they are system-integrated components. Feeding consistency, shot angle tolerance, and collation integrity directly affect the performance of modern nailing machinery.

The geometry of 21°, 28°, or 34° is not simply mechanical—it’s algorithmic. These angles are part of a broader optimization, integrating tool rhythm with operator productivity.

2. Invisible Craftsmanship, Visible Impact

From the tensile strength of the wire to the cohesion of the paper tape, every detail of paper strip nail production is driven by performance data and high-speed feedback. An unstable paper strip increases jamming rates, while poorly aligned nails accelerate tool wear and raise downtime costs.

Behind a reliable nail strip lies a devotion to micron-level tolerances, ensuring batch consistency and operational integrity across global markets.

3. Silent Drivers of Sustainability

Paper strip nails are often praised for their eco-friendly materials, but their real value lies in systemic sustainability. Unlike plastic or metal collated nails, the paper tape is biodegradable and safe under combustion, making them ideal for green building and carbon-neutral projects.

They're not just low-waste—they’re low-intervention. Fewer jams, less residue, and smoother workflows all contribute to a more efficient, cleaner site environment.

4. The Philosophy of Form in Global Supply Chains

In a world of fractured logistics and rising compliance thresholds, the humble paper strip nail has become a strategic product. Certifications like CE, batch precision, and the ability to customize according to regional tool specs and materials regulations have turned them into compliance anchors in multinational procurement systems.

To a global buyer, a paper strip nail is not just a fastener—it’s a sign that the supplier understands the architecture of production.

Conclusion

As the smallest unit in a large operational chain, paper strip nails now hold symbolic and practical weight. They reflect the evolution of production ethics, the sophistication of tooling ecosystems, and the industry’s shift toward sustainable, intelligent manufacturing.

To manufacture paper strip nails today is not simply to make nails. It is to engineer trust, rhythm, and resilience—one strip at a time.

Post time: Jul-11-2025