In modern construction and timber framing, the choice of fasteners directly affects the strength, safety, and durability of the structure. Among the most widely used fastening solutions, N-type nails stand out for their superior performance, versatility, and reliability.

N-type nails are typically used for heavy-duty framing, wall studs, roof decking, sub-flooring, and general wood-to-wood connections. They are available in smooth shank and ring shank designs. The ring shank variety provides significantly higher withdrawal resistance, making it ideal for high-load structural environments where stability is critical.

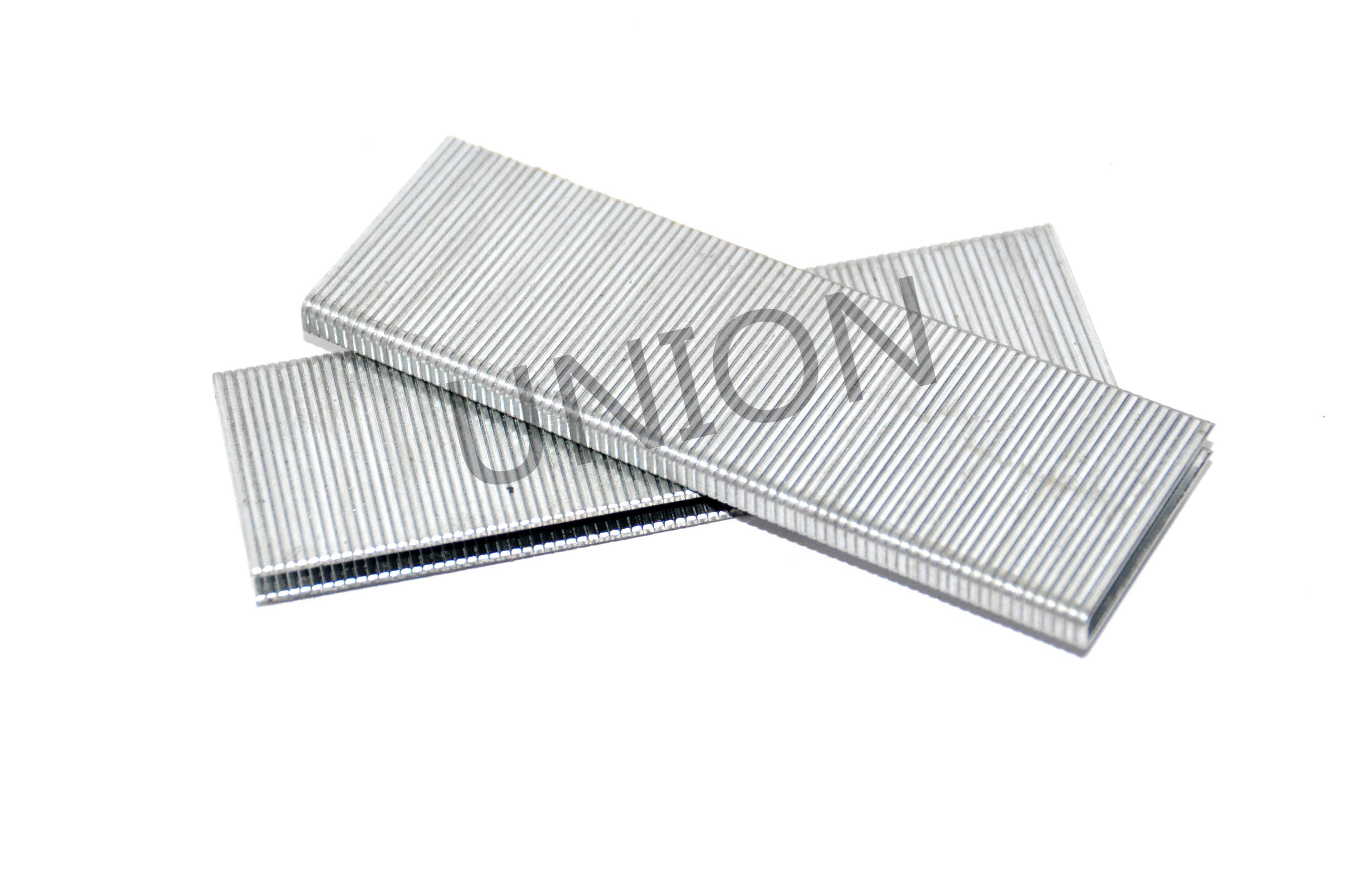

One of the key advantages of N nails is material adaptability. These nails are produced in bright steel for indoor applications, galvanized coatings for moisture-prone areas, and stainless steel for extreme or corrosive conditions. With lengths ranging from 2″ to 3.5″, and various diameters, N nails provide tailored fastening solutions for a wide range of construction needs.

Beyond strength and durability, N-type nails contribute to construction efficiency. They are commonly used with pneumatic nail guns, allowing for fast, repeatable installation while reducing labor time and error. This compatibility with automated tools aligns perfectly with today’s emphasis on industrialized and standardized building practices.

In high-performance framing systems, sub-floor assemblies, and exterior sheathing, the use of high-quality N-type nails enhances both short-term structural integrity and long-term durability. Their proven reliability makes them a top choice among contractors, framers, and builders seeking dependable fastening solutions.

Investing in the right N nails means not only improving construction efficiency, but also ensuring safety, longevity, and compliance with modern building codes.

Post time: Jun-19-2025