Products

-

3-axis CNC double-head chamfering and marking machine

Automatic double-head chamfering machine’s clamping die and cutter plate, after exquisite design, to ensure that the centre line of the processing object and the cutter plate is accurate and unchanged, can be uniformly completed at a time, to ensure the processing of the accurate size, through the vibration plate automatic loading, greatly improve the production efficiency and save manpower.

-

Paper strip nails

Length:110mm-160mm

Purpose:Suitable for decoration, installation of wood products, fixing of packing boxes.

-

Concrete Nailer

With harden treatment magazine, makeslonger service life.

Durable fring pin group and O-ring. Strong strength,and rapid air-return.

Gun body strengthening heat treatment is firm, stable and safe 12.9 high strength six angle screw, durable.

-

Magnetic feeding machine

Magnetic loader is a specialized equipment for conveying ferrous items (such as nails, screws, etc.) to a specified location, which is widely used in manufacturing and assembly lines. The following is a detailed description of the magnetic loader:

Working Principle

Magnetic loading machine adsorbs and transfers ferrous articles to the designated position through the built-in strong magnet or magnetic conveyor belt. The working principle mainly includes the following steps:Object adsorption: Ferrous objects (e.g. nails) are evenly distributed at the input end of the loading machine by vibration or other means.

Magnetic transfer: A built-in powerful magnet or magnetic conveyor belt adsorbs the articles and moves them along a set path by mechanical or electric drive.

Separation and Unloading: After reaching the specified position, the items are dislodged from the magnetic loader by demagnetizing devices or physical separation methods to proceed to the next processing or assembly step. -

Ordinary thread rolling machine US-1000

Thread rolling machine is the equipment for producing nails. There are various types of thread rolling machines, which can satisfy the different needs of the market for various kinds of nail production. Thread rolling machine is simple, sensitive, efficient and has other similar equipment can not be replaced.

-

High speed thread rolling machine US-3000

Thread rolling machine is the equipment for producing nails. There are various types of thread rolling machines, which can satisfy the different needs of the market for various kinds of nail production. Thread rolling machine is simple, sensitive, efficient and has other similar equipment can not be replaced.

-

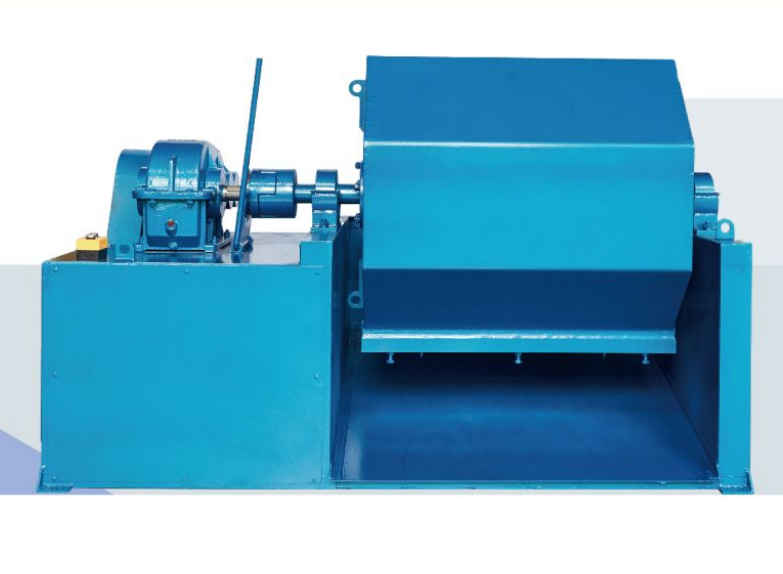

Nail washing machine

The wire nail polishing machine is also named nail washing machine. It removes burrs and polishes the nails processed by the nail making machine through high-speed rotating friction, and is used to derust and polish the semi-finished round nails just produced. The nail polishing machine is an indispensable special equipment in the nail making industry.

The nails are dirty with some oils when drop from the nails making machine automatically. Also, many clouds of dust in nails making plants. So we need a wire nail polishing machine to make common wire nails more shining.

-

Bright Wire Straight Line Wire Drawing Machine

Technical Specifications Size Max inlet Min Outlet Drawing Number Average Reduction Rate General Reduction Rate Max Speed Motor Power Noise Annealing Reduction Rate Φ1200 Φ8mm Φ5.0mm 1-9 ≤ 20% 60% 120M/min 90KW 132KW 80db 60% Φ900 Φ12mm Φ4mm 1-10 ≤ 20% 60% 240M/min 75KW 110KW 80db 60% Φ700 Φ8mm Φ2.6mm 4-13 ≤ 20% 60% 600M/min 30KW 45KW 80db 70% Φ600 Φ7mm Φ1.6mm 4-13 ≤ 20% 60% 720M/min 18.5KW 37KW 81db 80%... -

GALVANIZED FIELD FENCE

MATERIAL:CARBON STEEL Q195

APPLICATIONS:FACILITATE THE PLANNED USE OF GRASSLAND RESOURCES AND EFFECTIBELY IMPROVE GRASSLAND UTILIZATION AND GRAZING EFFICIENCY.AT THE SAME TIME,IT IS ALSO APPLICABLE TO THE ESTABLISHMENT OF FAMILY

FARMS WITH FARMERS AND HERDSMEN, THE ESTABLISHMENT OF BORDER DEFENSE, FARMLAND FENCE, FOREST NURSERY, CLOSING MOUNTAINS FOR AFFORESTATION, THE ENCLOSURE OF TOURIST AREAS AND HUNTING AREAS, AND THE ISOLATION AND MAINTENANCE OF CONSTRUCTION SITES.

-

Horizontal/Vertical Spooler

allows collecting the wire on the spooler. It is provided with wire guide at variable pitch.

-

Wet Wire Drawing Machine

Wet Wire Drawing Machine

Suitable for drawing high strength wires,such as tyre cord,PV silicon cutting wire

-

Straight-Line Wire Drawing Machine LZ-900-1000-12000

Wire Drawing machine is widely used in industrial applications, widely used in machinery manufacturing, hardware processing, petrochemicals, plastics, bamboo and wood products, wire and cable and other industries.