Products

-

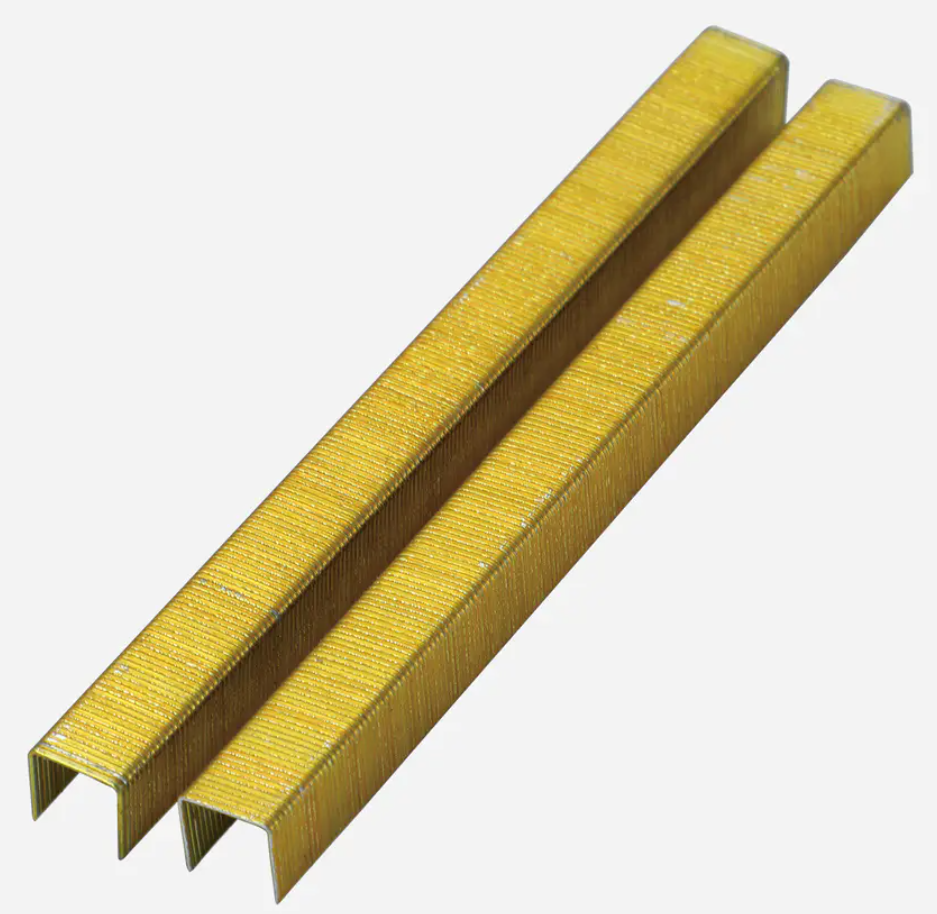

14 Series Staples

Product material: carbon steel

Product standard: GB/YB

Surface treatment: galvanized/yellow

use

In the furniture manufacturing industry, it is used for sofa chairs, sofa fabrics and leather, in the decoration industry, it is used for ceilings and thin plates, and in the wooden box industry, it is used for outer thin plates.

-

Barbed Wire

Barbed wire is twisted and braided by a fully automated barbed wire machine. Types of finished products: monofilament twisted braid and double-filament twisted braid. Raw material: high quality low carbon steel wire. Surface treatment process: electro-galvanized, hot-dip galvanized, plastic coated, sprayed. Available in blue, green, yellow and other colors. Uses: Used for pasture boundary, railroad, highway isolation protection.

-

Razor Barbed Wire

When you need to get serious about security, Razor Barbed Wire is the best solution. It is relatively inexpensive, but viciously effective. Razor Barbed Wire around the perimeter is enough to deter any wouldbe vandal, robber or saboteur. Razor Wire is made of a corrosion resistant galvanized steel cutting ribbon wrapped around a core of galvanized spring steel wire. It’s impossible to cut without highly specialized tools, and even then it’s a slow, dangerous job. Razor Barbed Wire is a long lasting and very effective barrier, known and trusted by security professionals.

-

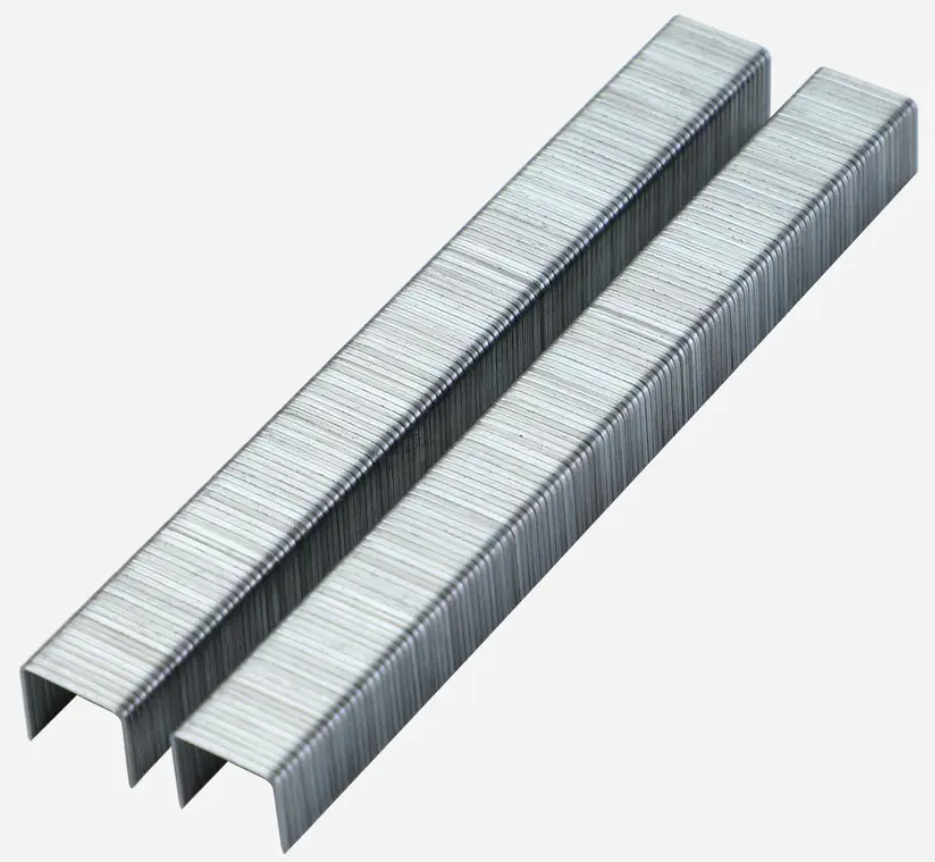

92 Series Staple

Material:Carbon Steel

Standard:GB/YB

Surface treatment: galvanised

Usage

Furniture manufacturing industry for sofa chairs, sofa cloth and leather, decorative industry for ceiling, sheet, wooden box industry for outer layer of sheet.

-

80 Series Staple

Material:Carbon Steel

Standard:GB/YB

Surface treatment: galvanised

Usage

Furniture manufacturing industry for sofa chairs, sofa cloth and leather, decorative industry for ceiling, sheet, wooden box industry for outer layer of sheet.

-

Door and window staples

Material:Carbon Steel

Product Standard:GB/YB

Surface treatment: galvanised/black

Usage:For fixing and linking aluminium doors and windows as well as thin iron sheets.

-

Hexagonal Mesh Machine

Smooth operation,low noise,fast weaving speed.The whole equipment is driven by a 2.2KW motor,saving electricity.More labor-saving,as a result of the elimination of the spring process,one equipment is enough,skilled workers can operate two equipment.

-

Magnetic feeder

Process Description:The workpiece is poured into my hopper (with a spring) from the material frame, and there is a vibration device under the hopper. The vibration device works to evenly distribute the workpiece in the hopper on the raised conveyor belt. There is a strong magnetic field on the back of the conveyor belt, which sucks the workpiece from running along the red trajectory to the top. When the strong magnetic field reaches the top, it is recycled, and the workpiece falls into the next working plane of the process.

-

10J Series Staples

Material:Carbon steel

Standard:GB/YB

Surface Treatment: Galvanised

Usage: Furniture manufacturing industry for sofa chairs, sofa hair and leather, decorative industry for ceilings, sheet, wooden box industry for the outer layer of sheet.

-

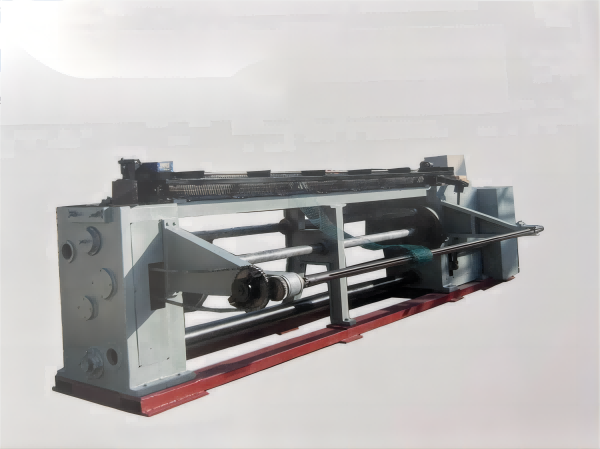

Three-axis thread rolling machine Z28-16

The machine is mainly composed of three identical sets of thread rolling shaft assemblies,three sets of identical sliding sleeve cylinder hydraulic systems.transmission mechanisms, shifting mechanisms,electrical systems,and cooling systems.

The fuselage supports three identical cylinders, and the cylinder bottom supporta three identical thread rolling shaft assemblies for synchronous feed and retraction linear motion.The clamping of the workpiece is completed,and the retracting process is cut in and released;the three output rolling shafts of the transmission output drive shaft rotate in the same direction at the same speed to complete the rolling process of the thread.

-

K Series Staples

Material:Carbon steel

Surface Treatment:Zinc Plating

Used in the furniture industry for stapling of sofas, chairs, fabrics and leathers, in the upholstery industry for the installation of ceilings and panels, and in the crate industry for the stapling of outer panels. -

N Series Staples

Material:Carbon steel

Surface Treatment:Zinc Plating

Furniture manufacturing industry for sofa chairs, sofa cloth and leather, decorative industry for ceiling, sheet, wooden box industry for the outer layer of sheet.