Products

-

Thread Rolling Machine Model Z28-200

This model mainly is used for pressing precision standard parts of extermal thread and high strength,including regular thread,trapezoid thread and modulax thread.The objective material to be processed inchcde carbon steel,alloy steel and nonferrous metal with elongation over 10% and tensile strength less than 1000N/mm2.This machine can be based on user demand is equipped with automatic feeding device.

-

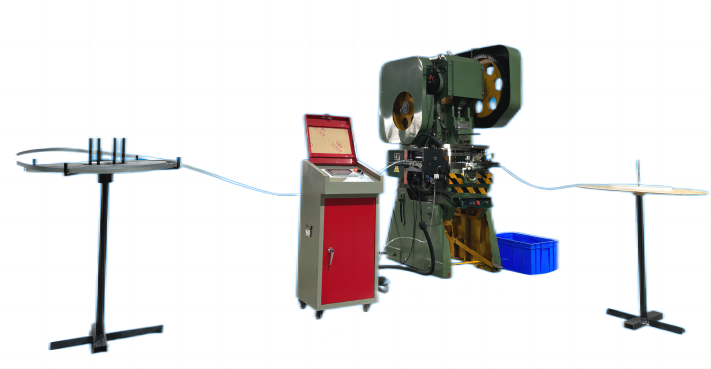

Sofa Spring Clips Machine

Customized available

NC numerical control feeding system

Highly efficient refining automatic press(non-standard) 25T/30T/40T/63T

Advanced two-in-one automatic mold.

Automatic detection and protection system.

Efficient, stable, easy to operate and maintain.

-

Eye Bolts Making Machine

Eye bolts making machines are advanced manufacturing equipment designed to automate the process of bending and shaping metal rods into eye bolts. These machines are developed using cutting-edge technology to ensure precise and consistent production. With their adjustable settings, eye bolts making machines can adapt to different specifications and sizes, making them suitable for a wide range of applications.

-

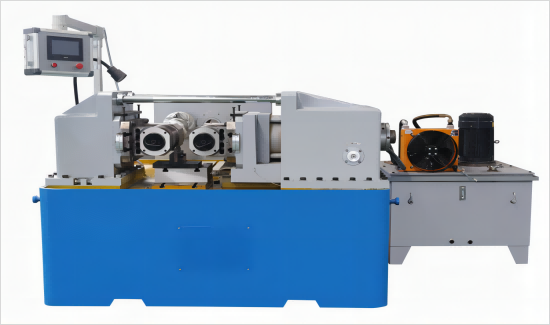

Thread Rolling Machine Model Z28-400

The construction of the Z28—400 model i made with welded steel plates, this machine boasts a rational structure, which contributes to its overall rigidity and stability. This robust build allows for precise and accurate thread rolling, resulting in superior quality products.

Moreover, the Z28—400 model prioritizes ease of operation. Its user-friendly interface and intuitive controls make it accessible for both experienced operators and those new to the thread rolling industry. The simplicity of its design translates into quick setup and adjustment, further streamlining the manufacturing process

-

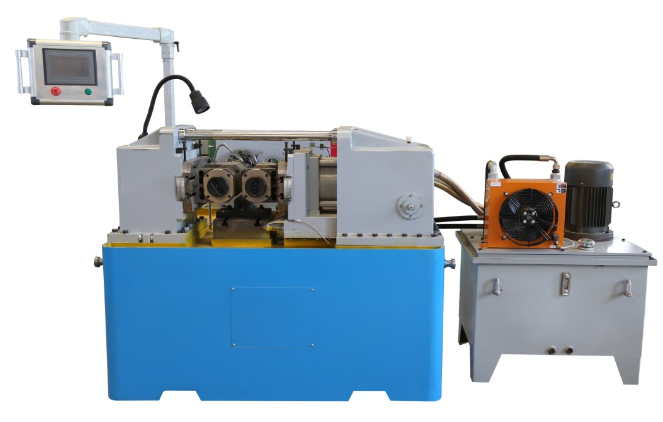

Thread Rolling Machine Model Z28-260

This model mainly is used for pressing precision standard parts of extemal thread and high strength, including regular thread .rapezoid thread and modulax thread.The objective material to be processed inchcde carbon stel,lly steel and noferrous metal with elongation over 10% and tensile strength less than 1000NV/mm’. This machine can be based on user demand is equipped with automatic feeding device.

-

Clip Nail Coil Machine

The Clip Nail Coil Machine features an adjustable number of clips to shear, allowing the user to set it as desired.

-

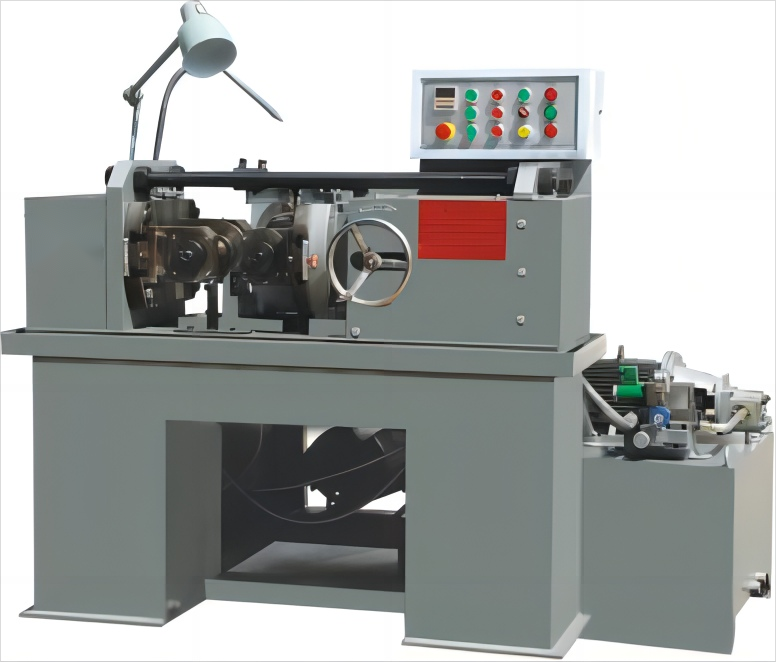

Thread Rolling Machine Model Z28—40

This machine is suitable for rolling forming straight, screw and ring type,etc, with a diameter of of Ø4-Ø36 in cold state. Equipped with screw moulds, it’s also capable of manufacturing concealed wire (threads hidden inside the workpiece)、total screw. Formed by welding steel plates, this machine possess reliable quality, reasonable structure, and it’s easy to operate. We believe this is the ideal machine for you to produce standard and even non-standard thread.

Automatic feeding device is available to be equipped according to your demand.

-

Winding Machine

Equipment structure reasonable design,whole beautiful, rigid and small error,high precision.

Equipment is hightly effective,the energy conservation,safety,production as high.

The most significant characteristic is equipment good stability,easy operation,easy maintenance,full automatic lntelligent,the vulnerability of low cost.

-

Nut forming machine

A nut forming machine is a specialized device used in the manufacturing of nuts. Nuts, as commonly known in the hardware industry, are small metal pieces used to fasten objects together. These essential components are found in various industries, including automotive, construction, and aerospace, among others. Traditionally, nut production required multiple steps, including casting, machining, and threading. However, with the invention of the nut forming machine, this process has become significantly more efficient.

-

HB- X90 High Speed Nail Making Machine

Another notable feature of the HB-X90 is its versatility. This machine can produce a wide range of nail types and sizes, accommodating the diverse needs of manufacturers. Whether it is for common nails, roofing nails, or specialty nails, the HB-X90 can handle the task efficiently. This versatility provides manufacturers with the flexibility to adapt to market trends and fulfill the specific requirements of their customers.

In addition to its superior performance, the HB-X90 High Speed Nail Making Machine also prioritizes safety and ease of use. It is equipped with advanced safety features to protect operators from accidents or injuries. The machine is also designed with user-friendly controls, minimizing the learning curve for operators and enabling faster production ramp-up.

-

Totally-Enclosed Self Drilling Screw Thread Rolling Machine

The thread rolling machine mainly uses two pieces of the same,the thread rolling surface has the same tooth shape with the bolt thread of the same helix Angle of the same tooth shape,in the mutual movement of the thread rolling plate between the two screw plates to rub out the thread. The thread board is processed once and once with a bolt thread,which has the characteristics of high efficiency,high precision and reduced labor cost.Suitable for professional mass screw thread production and processing.

-

Type Fencing Staple Making Machine

This forming machine can make the wires to be any shape according to the moulds, has the advantages of low noise and convenient adjustment etc.