- Coil nail machine

- Magnetic feeder

- Nailer

- Nail making machine

- paper collator

- Plastic strip nail making machine

- Self drilling screw machine production line

- Bar thread rolling machine

- Staple

- Staple making machine

- Clip nail making machine

- Steel bar straightening cutting machine

- Wire mesh

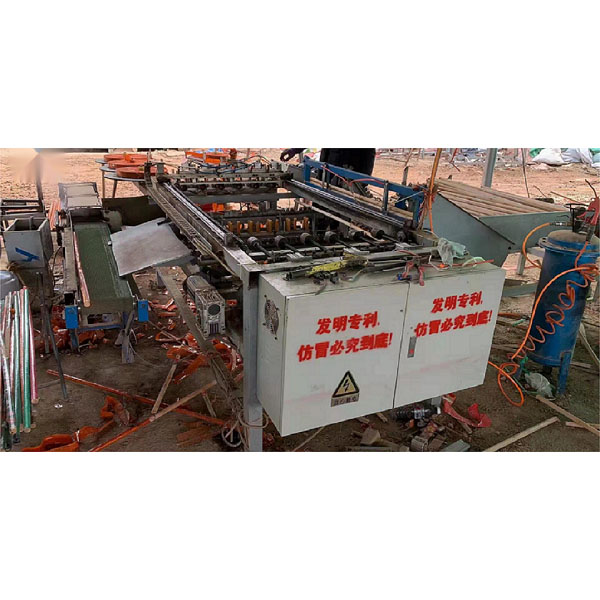

- Wire Mesh Machine

- Nail

- Wire drawing machine

- Wood Sawdust Blocks Production Line

Other machines

-

Galvanized strip

Description

Zinc coated

Size(mm)

internal diameter

(mm)

Galvanized coils

40-60g

0.76*11

508

-

Heading machine

Model

Max.Cut diameter

Max.Blank Length

Stroke

Output rate

Main Die Diameter

Cut-off Die Diameter

unit

mm

mm

mm

pcs/min

mm

mm

DSH-15

6

35

70

60

46

19

DSH-20

7

50

90

50

50

28

PunchDie(1st)

PunchDie (2nd)

Body MotorPower

L*W*H

Weight

mm

mm

KW

mm

KG

31

31

4

2260*1230*1260

2500

31

31

7.5

3230*1480*1520

5000

-

U-Type bolt forming machine

Technical Parameters:

Rang

Ø12mm-Ø30mm

Center Distance

60mm-200mm

Height

100mm-500mm

Motor

15kw

Working Efficiency

5-8pcs/min

Oil Cylinder

45T

Size

1500X800X1000mm

Weight

1200KG

-

Thread rolling machine

The working principle of thread rolling: it is two identical pieces, the thread rolling surface has the same tooth shape as the thread shape of the bolt thread and the same helix angle. When the thread rolling plates move with each other, the bolt blank between the two thread rolling plates is rubbed out of the thread . The thread rolling plate goes back and forth one bolt thread at a time to complete the processing, and the speed is quite high.

Equipment advantages: strong steel, high precision, long service life, etc. In the thread processing process, the problem of easy loss of the worm gear and worm is solved, and the noise caused by the friction of the worm gear and worm is also reduced. Stepless frequency conversion, free adjustment, easy to use.

-

Broom handle PVC coating machine

The broom handle PVC coating machine mainly used for producing the wooden broom with PVC coated, and equipped with automatic discharging conveyor. Our machine can process 6 pcs broom handles at one time. The advanced U shape heating technology assures that the brooms are heated evenly.

The machine is mainly used for film sealing, cutting and packaging of broom handle. Put the rod that needs to be packaged into the push tray and push it in manually, then seal and cut. The suitable packaging material for this machine is PE film, which greatly saves labor costs compared with traditional manual lamination.

The laminating machine uses heat shrinkage to firmly cover the PE bag on the mop rod, so that the mop has a perfect packaging effect.