Products

-

High-Speed Thread Rolling Machine

This machine serves the production of new types threaded nails and ring shank nails. It matches many types of special molds, which gives it the ability to produce diverse abnormal-shape nails.

This machine is designed and manufactured according to American standard. With features such as reliable main shaft, variable speed integration of cabinet, circulation cooling of machine oil, it has advantages of high accuracy and high output, and therefore occupies the leading place in all machines we have produced.

-

Drywall Nail

Surface treatment: black phosphate/blue white zinc/colour zinc plating

Material: carbon steel

-

Fiberboard nails

Surface treatment: heat treatment process color zinc plating

Product material: carbon steel

-

ST-Type Brad Nails

Surface treatment: galvanized

Product material: carbon steel

-

F Series Staples

Used in wooden pallets, wooden packing boxes, home sofas, decoration, footwear industry, wooden house construction.

Material:Carbon stee

Surface treatment: galvanised

-

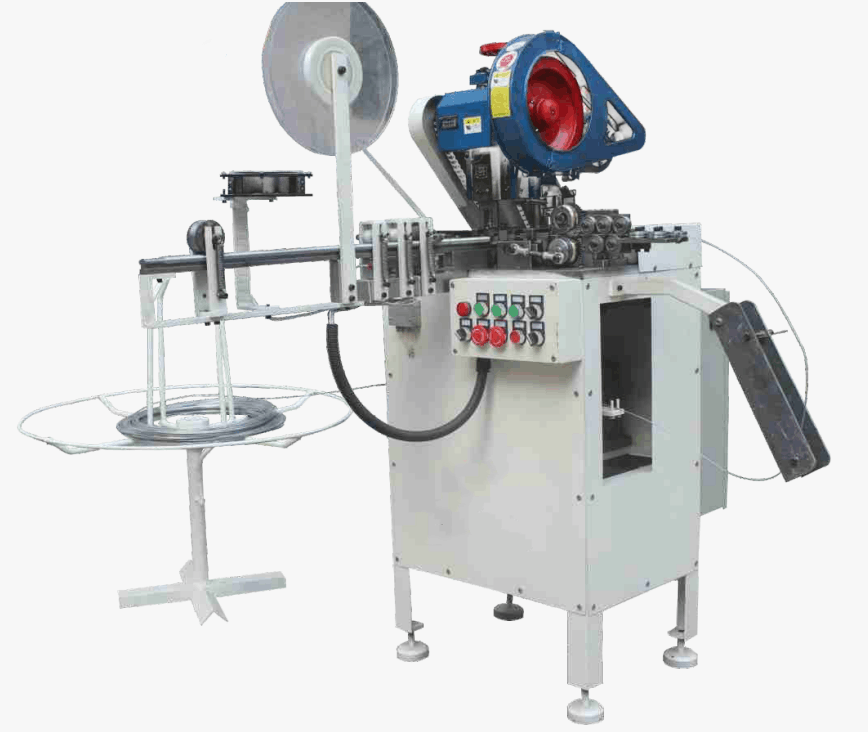

Paper fastening machine with mechanical arm

This machine is designed by our company and can produce paper strip nail and offset nail head paper strip nail. It can also produce automatic nut and partial automatic nut with clearance paper ordering nails, The nail row angle is adjustable from 28 to 34 degree. The nail distance can be customized. It has reasonable design and excellent quality.

-

Plastic Strip Nail Making Machine

The plastic strip nail machine is researched and produced according to the technical equipment of Korea and Taiwan.We combining the actual production situation and improve it.This machine has the advantages of reasonable design,simple operation and high efficiency etc.

-

Fully Automatic Seat Type C-ring Machine

The equipment has beautiful appearance, scientific and reasonable structure, convenient operation, stable and reliable performance, low noise, high efficiency, low loss, and can produce 250-320 nails per minute.The products are mainly used for the connection of mattresses, car cushions, sofa cushions, pet cages, rabbit cages, bag springs, chicken cages and fences in the breeding industry.

-

Eye Bolt Thread Rolling Machine

Our engineers have been focusing on R&D machines for many years and our machines have been upgraded generation by generation. Produce machine by our experienced team according to customer requirement.Assist customer to select the most suitable machine and give them our professional suggestion. Provide customer operation manual or video for machine to help them operate machine more eficiently.

-

D90-NAIL MAKING MACHINE

Advantage:

1.Double die and double punch mold structure (two dies . Two punches. A nail knife, made of imported alloy, the service life is 2-3 times of the ordinary mold)

2. Reduce the cost of nailing (800 nails / minute speed effectively reduce 50% -70% of the nail maker)

3. Reduce the cost of rolling nails (eliminate long and short nails. Partial cap. Nail cap size is not the same. Waste machine head. Bent nails. Effectively reduce 35%-45% of nail rollers)

4. Greatly increase the weight of products and reduce production costs (increase in the efficiency of nailing and coiling nails. Large reduction of scrap nails. Reduction of energy consumption, etc. at least effectively reduce the production cost of coil nails more than 100 yuan / ton. Enhance the core competitiveness of the factory)

5. Power saving. Motor power total 7KW, the actual use of only 4KW / hour (frequency control)

6. Improve the parameter: according to the wire diameter 2.5. length of 50 coiled nail calculation, ordinary 713 nail-making machine 8 hours can produce 300kg nails, and high-speed machine power on the output of 1 hour can reach more than 100kg (nail-making parameter is more than 3 times the ordinary machine)

7. Saving space in the plant (the efficiency of 1 high-speed machine can be more than 3 sets of ordinary machine)

-

High Speed Nail Making Machine

Our High Speed Nail Making Machine is its ability to significantly reduce labor costs. By eliminating the need for additional workers, businesses can save on salary expenses. This machine is so efficient that it does not require constant monitoring or nursing after it has been set and adjusted. This means that you can put your trust in our machine and focus on other important tasks, while it continues to produce high-quality nails effortlessly.

-

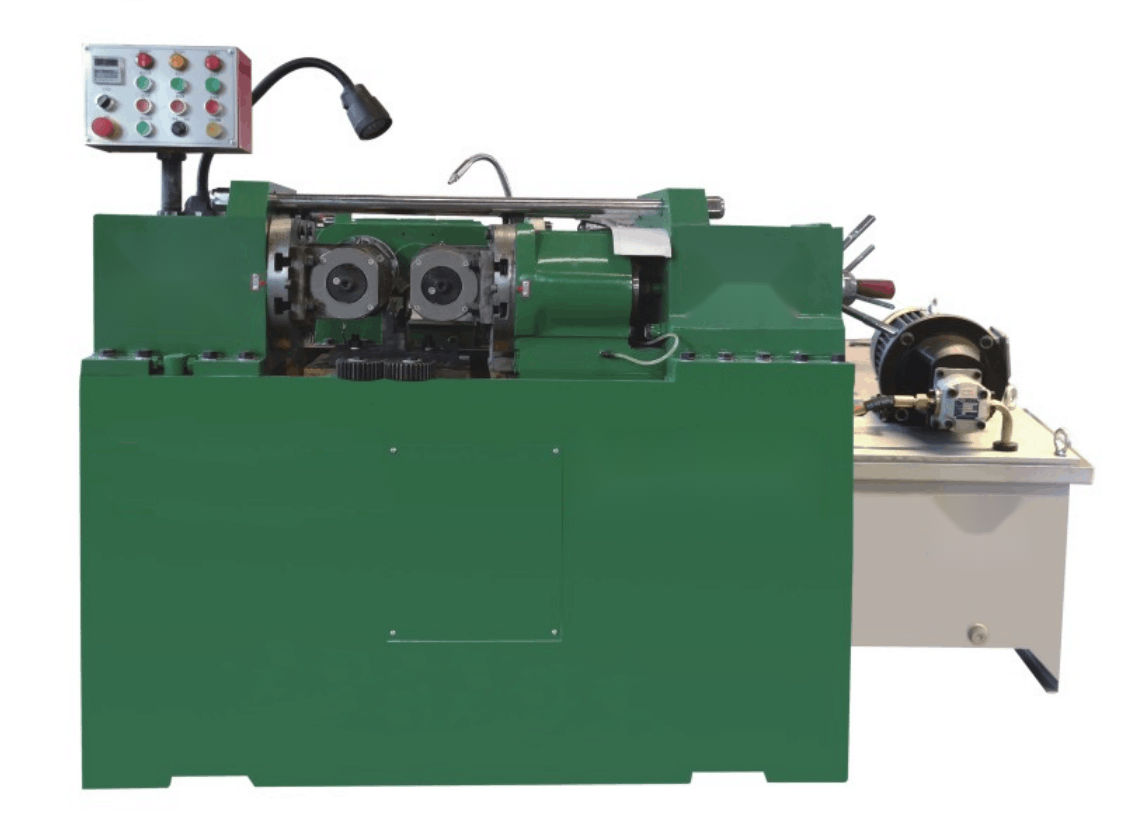

Thread Rolling Machine Model Z28-80

This model is widely praised for its rational price,easy maintenance and high quality.Besides axial and radial process,it is used to process regular and irregular bolt,through screw etc.with optional embossing roller.The through screw made with this machine in ZheJiang Standard Parts base has been exported to US,Canada and Europe. This machine can be based on user demand is equipped with automatic feeding device.