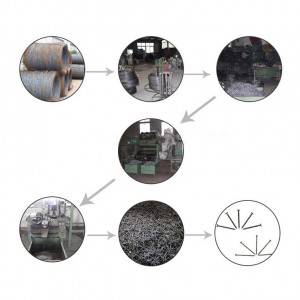

Thread Rolling Machine/ring shanker machine

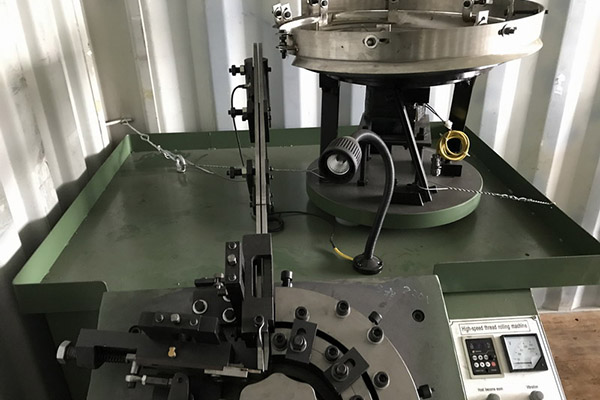

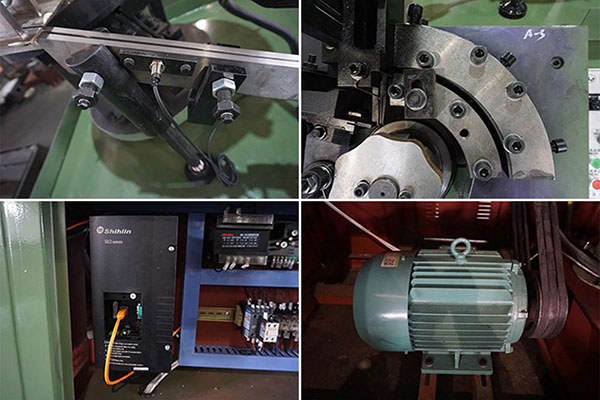

The high-speed screw rolling machine produced by our company is researched and manufactured according to the principle of American imported machine, adopts main shaft and variable speed integration of cabinet, the machine oil in cabinet is in circulation cooling, has the advantages of high accuracy, high output, stable quality, durable in use and convenient operation etc. occupies the leading place in similar products in our company.

This machine matches with all kinds of special molds, can produces all kinds of abnormal-shape nails, mainly used in new-type nails of threaded nails and ring shank nails etc.

| Motor powder of machine(kw) | 5.5 |

| Coil nail diameter(mm) | 1.8-4.5 |

| Coil nail length(mm) | <100 |

| Weight(kg) | 1500 |

| Production Speed(unit/second) | 1200 |

| Overall dimension(mm) | 1400*1500*1600 |

High-speed thread rolling machine is a professional equipment for producing screw threads. According to the difference of professional standards, there are various types of high-speed thread rolling machines, such as flat-plate thread rolling machines, semi-automatic thread rolling machines, automatic thread rolling machines, etc. There are various types of thread rolling machines, which can meet the different needs of the market for the production of various screws. This equipment uses the parallel sliding of parallel tooth plates to form threads, which is a kind of cold kneading processing. After being extruded and formed by the surface of the thread rolling machine, the strength is higher than that of ordinary machining. The deformation of thread rolling is usually not large, which can well maintain the stability of the product and make its shape difficult to change.