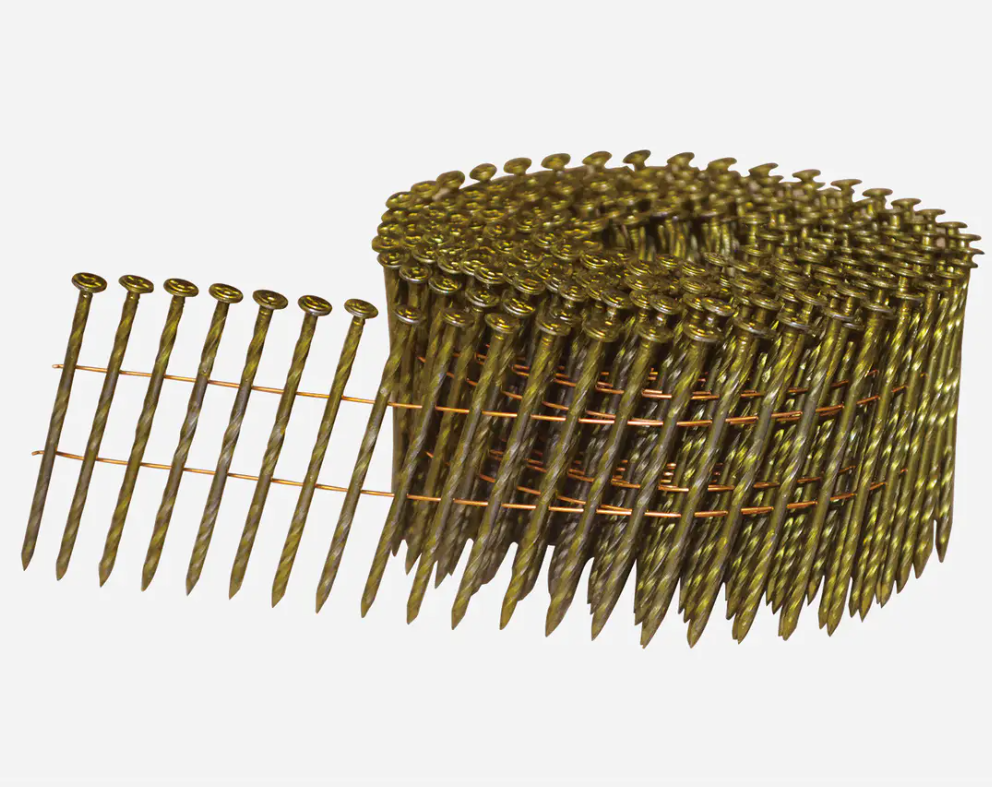

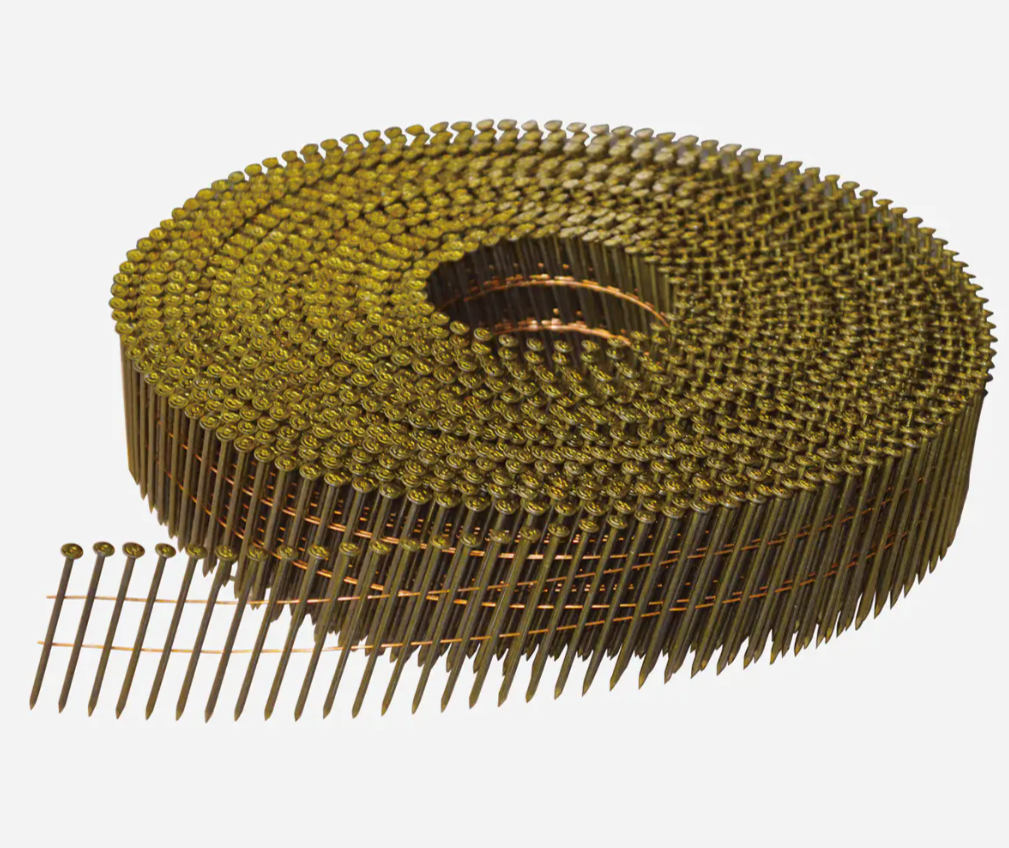

3000pcs per coil jumbo coil nails

The quality of the bright silk after a roll of nails and roll nails is 300kg. The nail -making mechanism nails are used. When making nails, you need to choose different molds according to the size of the product. In the vibration disk of the rolling machine, the nails will enter the guide rail in an orderly manner through the vibration nail, and then fall into the nail wheel. In this section of the plane, paint slots and brushes are added, and paint buckets and special light bulbs are added to it. When the rolling nails are passed, the paint and dryness are completed. The rolled nails are automatically cut off by the infrared counters on the nail wheel according to the number of pre -set, and then the workers roll into the finished product through the scroll and load them in the corresponding packaging box.

1. The production of a rolling nail, which is characterized by the drying of the steps (a) to prepare the metal materials required for nails; Cold steel after cleaning; (C) drawing CD) Nails, rolling nails arranged nails and rolled nail machines, metal materials were nails through the nails of the nails, Paint in the process.

2. The production of rolling nails according to the claim I is characterized by the immersion paint in the step (d), and the rolling nails are immersed in the quick -drying paint.

The present invention has disclosed a production process of rolling nails, including de -oxidation leather, drawing, nails, and rolling nails. By changing the process steps, the invention is added to the dek -oxide process before drawing. Rough, because the present invention will implement the nail -making process and roll nails at the same time, and immerse the paint in the process of rolling nails, which will help reduce the loss of raw materials and improve production efficiency. The pollution of the present invention is simple and has a clear effect, which is suitable for industrial production.