- Coil nail machine

- Magnetic feeder

- Nailer

- Nail making machine

- paper collator

- Plastic strip nail making machine

- Self drilling screw machine production line

- Bar thread rolling machine

- Staple

- Staple making machine

- Clip nail making machine

- Steel bar straightening cutting machine

- Tent

- Wire mesh

- Wire Mesh Machine

- U-Type bolt forming machine

- Nail

- Galvanized strip

- Wire drawing machine

- Wood Sawdust Blocks Production Line

- Spare parts

- Fully Automatic Seat Type C-ring Machine

- Other machines

Nail Making Machine Serier

-

Ordinary thread rolling machine US-1000

Parameter Model US-1000 Max dia 3.6 Min dia 1.8 Lgenth < 100 Speed 0-1200pcs/min Total cooling power 0.12kw Motor power 5.5kw Total installed power 8kw size 1500*1400*1500mm Weight 1200kg -

High speed thread rolling machine US-3000

Parameter Model US-3000 Max dia 3.6 Min dia 1.8 Lgenth < 100 Speed 0-3500pcs/min Total cooling power 0.7kw Motor power 7.5kw Total installed power 10kw size 1900*1500*1800mm Weight 1800kg -

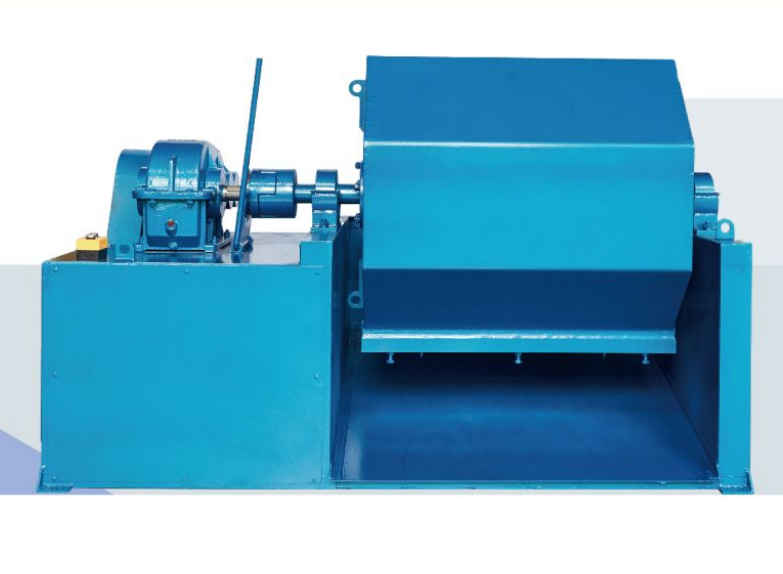

Nail washing machine

Parameter Speifications 400KG 600KG 1000KG 1500KG 2000KG 2500KG Dimensions (length * width * height) 1850*1000*1400 1850* 1000*1400 2110*1300*1450 2600*1400*1650 3180*1400*1460 3680*1400*1650 Motor power 4KW 4KW 7.5KW 11KW 11KW 15KW Gearbox 250Gearbox 250Gearbox 350Gearbox 400Gearbox 400Gearbox 500Gearbox Machine weight 650KG 650KG 850KG 1300KG 1300KG 2100KG Capacity 480KG 480KG 800KG 1200KG 1200KG 2000KG 8-hour production 1440KG 1440KG 2400KG 3600KG 3600KG 6000KG Single barr... -

D50 high-speed nail making machine

specification Model Parameter Max dia 2.8mm Min dia 1.8mm Max length 55mm Min length 25mm Speed ≤800pcs/min Motor power 5.5kw+1.5kw Size Main engine 1500*950*1300mm Wire reel 1700*1100*1700mm Electric box 420*700*1050mm Weight Main engine Weight 2500kg Wire reel Weight 350kg Electric box Weight 50kg -

High-Speed Thread Rolling Machine

This machine serves the production of new types threaded nails and ring shank nails. It matches many types of special molds, which gives it the ability to produce diverse abnormal-shape nails.

This machine is designed and manufactured according to American standard. With features such as reliable main shaft, variable speed integration of cabinet, circulation cooling of machine oil, it has advantages of high accuracy and high output, and therefore occupies the leading place in all machines we have produced.

-

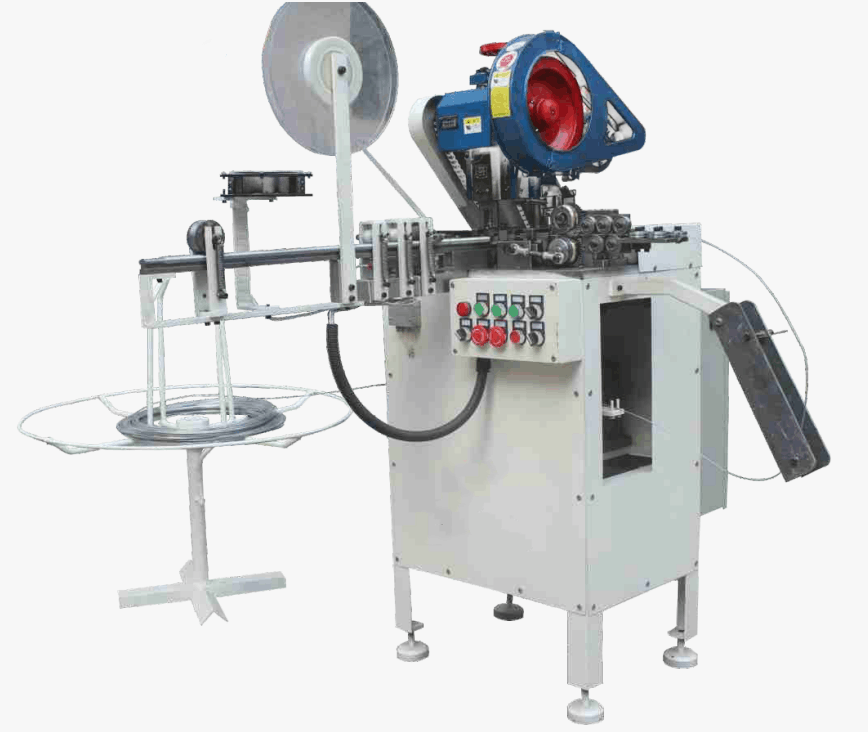

Paper fastening machine with mechanical arm

This machine is designed by our company and can produce paper strip nail and offset nail head paper strip nail. It can also produce automatic nut and partial automatic nut with clearance paper ordering nails, The nail row angle is adjustable from 28 to 34 degree. The nail distance can be customized. It has reasonable design and excellent quality.

-

Plastic Strip Nail Making Machine

The plastic strip nail machine is researched and produced according to the technical equipment of Korea and Taiwan.We combining the actual production situation and improve it.This machine has the advantages of reasonable design,simple operation and high efficiency etc.

Features:

1. The surface of the barrel is polished and beautiful

2. With a flip cover design, the feeding part is highly efficient and easy to clean

3. Special frame-type mixing helps to stir more evenly and get a stable performance

4. Stainless steel support, stable and beautiful

-

Fully Automatic Seat Type C-ring Machine

The equipment has beautiful appearance, scientific and reasonable structure, convenient operation, stable and reliable performance, low noise, high efficiency, low loss, and can produce 250-320 nails per minute.The products are mainly used for the connection of mattresses, car cushions, sofa cushions, pet cages, rabbit cages, bag springs, chicken cages and fences in the breeding industry.

-

D90-NAIL MAKING MACHINE

Our High Speed Nail Making Machine is built to deliver top-notch performance, producing nails of exceptional quality consistently. Its fast production rate ensures a high output capacity, allowing businesses to meet growing market demands without compromising on quality or delivery timelines. From construction companies to woodworking workshops, our machine is the perfect fit for any business that requires nails for their operations.

-

High Speed Nail Making Machine

Our High Speed Nail Making Machine is its ability to significantly reduce labor costs. By eliminating the need for additional workers, businesses can save on salary expenses. This machine is so efficient that it does not require constant monitoring or nursing after it has been set and adjusted. This means that you can put your trust in our machine and focus on other important tasks, while it continues to produce high-quality nails effortlessly.

-

Nut forming machine

A nut forming machine is a specialized device used in the manufacturing of nuts. Nuts, as commonly known in the hardware industry, are small metal pieces used to fasten objects together. These essential components are found in various industries, including automotive, construction, and aerospace, among others. Traditionally, nut production required multiple steps, including casting, machining, and threading. However, with the invention of the nut forming machine, this process has become significantly more efficient.

-

HB- X90 High Speed Nail Making Machine

Another notable feature of the HB-X90 is its versatility. This machine can produce a wide range of nail types and sizes, accommodating the diverse needs of manufacturers. Whether it is for common nails, roofing nails, or specialty nails, the HB-X90 can handle the task efficiently. This versatility provides manufacturers with the flexibility to adapt to market trends and fulfill the specific requirements of their customers.

In addition to its superior performance, the HB-X90 High Speed Nail Making Machine also prioritizes safety and ease of use. It is equipped with advanced safety features to protect operators from accidents or injuries. The machine is also designed with user-friendly controls, minimizing the learning curve for operators and enabling faster production ramp-up.