Products

-

US-ZDN AUTOMATIC NUT PAPER NAIL-ARRANGINGMACHINE

The automatic paper collator produced by independent research and development can produce the automatic nut and partial automatic nut with clearance paper

ordering nails,the nail row angle is adjustable from 0 to 34 degree.The nail distance can be ordered according to the requirement,it has the advantages of reasonable design,convenient

operation,excellent prope-rties and domestic first application

-

Concrete Nails

Purpose:Usage made of high quality carbon steel,used in decoration industry, fixing different structures of aluminum alloy and concrete.

Lenght:16mm to 150mm

-

Automatic coil nail making machine

Coil nail machine is a kind of automated production equipment, which works through a series of automated processes, including feeding, coiling, cutting and other steps, to achieve efficient production of finished nails.This coil nail machine is automatic welding equipment with high frequency and high speed. Place the iron nail in hopper to lay off automatically, the vibration disc arranges the order of nail to enter into the welding and form line-order nails, and then soak nail into the paint for rust prevention automatically, dry and count automatically to roll into roll-shape (flat-topped type and pagoda type). Automatically cut off according to the set number of each roll.

-

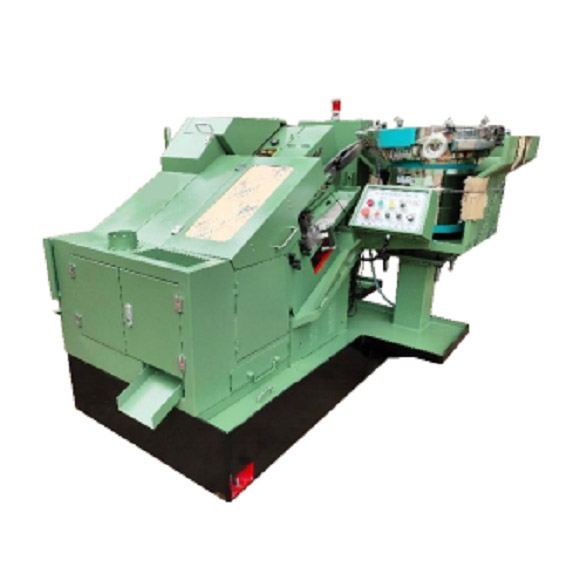

Heading machine

A heading machine is a powerful tool used for metalworking applications. It is used to shape and cut metal into specific shapes and sizes. This type of machine is used in a variety of industries, including automotive, aerospace, and manufacturing, and it has become an invaluable tool for both large and small businesses.

-

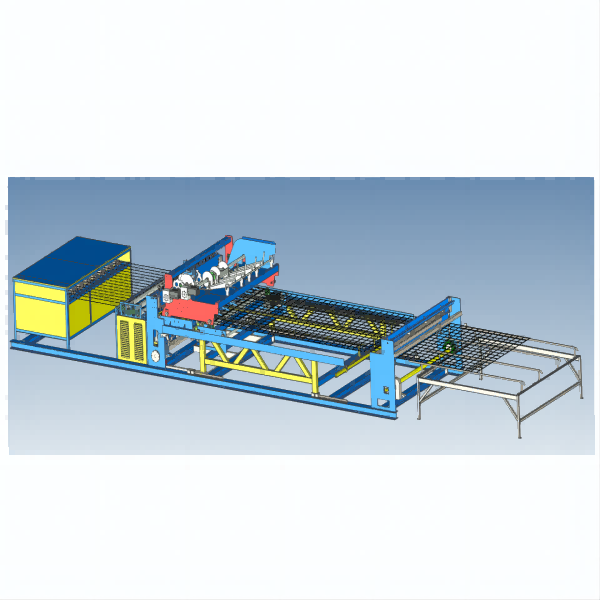

Welded mesh machine

Measure the length of the end of the weft wire according to the net drawing control system and record it in the computer, and at the same time send the weft wire to the welding transformer for automatic welding; the warp wire is automatically sent to the next weft wire by the electric welding machine; and through the control system completes the whole net pulling process.

-

Grassland network machine

Machine use:

Used for grassland nets, cattle pen nets, agricultural and animal husbandry professional households to establish family farms to establish border defense,

Production and manufacturing of farmland boundary fences, forest nurseries, mountain closures, tourist areas and hunting areas do.

-

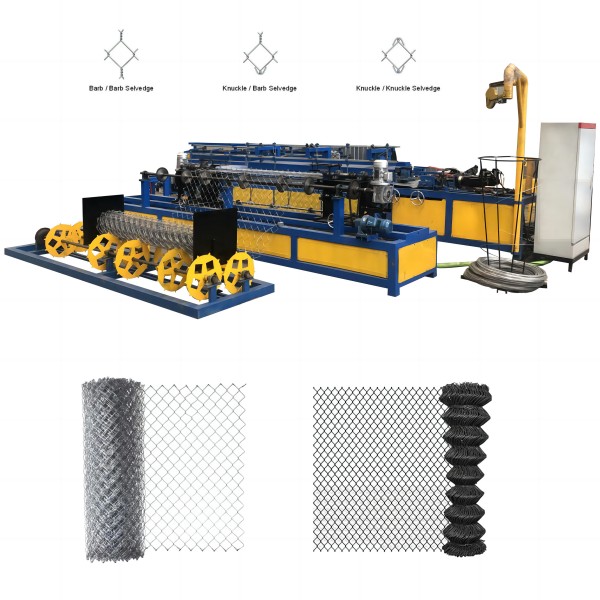

Chain link fence machine(double wire)

The chain link fence machine is also called the knitting machine. When it needs to be adjusted during use, it is operated manually, or it can be operated automatically according to needs. Chain link fence machine has been widely used in construction industry, highway, railway, bridge and other industries after years of development. With automatic edge locking function, the operation is simple and easy to learn.

-

U-Type bolt forming machine

This machine adopts horizontal push bending,the operation is simple and convenient.

-

Chain Link Fence Machine(Single Filament)

Chain link fence machine is also known as diamond net machine, coal mine support net machine, anchor net machine, chain link fence machine product display machine, net weaving machine. Chain link fence machine is a kind of wire mesh machine that crochets low carbon steel wire, stainless steel wire, aluminum alloy wire, PVC wire and plastic sprayed wire to form chain link fence. The mesh has uniform mesh, smooth mesh surface and beautiful appearance , The web width is adjustable, the wire diameter is adjustable, it is not easy to corrode and has a long service life, the weaving is simple, beautiful and practical.

-

Grassland Mesh Machine

Grassland Mesh Machine is a wrap-around fence net, which is characterized by being difficult to pull apart, full of elasticity, and the secondary net is not easy to rust.

-

Thread rolling machine

The working principle of thread rolling: it is two identical pieces, the thread rolling surface has the same tooth shape as the thread shape of the bolt thread and the same helix angle. When the thread rolling plates move with each other, the bolt blank between the two thread rolling plates is rubbed out of the thread . The thread rolling plate goes back and forth one bolt thread at a time to complete the processing, and the speed is quite high.

-

Self Drilling Screw Thread Rolling Machine

Efficient Forming: The screw thread rolling machine significantly reduces production cost by direct pressing method without cutting process and producing no waste. The high productivity of the machine ensures uniformity of thread finish and accuracy.

Enhanced Strength: Compared with traditional cutting process, thread rolling process produces threads with higher strength and more durable finished products, which are suitable for a variety of industrial applications.